Mathata a ho seha aluminium ke afe?

Alu alloy e bua ka "motsoako" o nang le tšepe ea aluminium le likarolo tse ling ho ntlafatsa litšobotsi tsa ts'ebetso. Lintho tse ling tse ngata li kenyelletsa koporo, silicon ea magnesium kapa zinki, ho bolela tse 'maloa feela.

Li-alloys tsa aluminium li na le meaho e ikhethang ho kenyelletsa ho hanyetsa kutu ho betere, matla a ntlafalitsoeng le ho tšoarella ha nako e telele, ho bolela tse 'maloa feela.

Aluminium e fumaneha ka mefuta e mengata e fapaneng ea li-alloys 'me letoto ka leng le ka ba le mefuta e fapaneng ea khalefo eo u ka khethang ho eona. Ka lebaka leo, li-alloys tse ling li ka ba bonolo haholo ho li sila, ho li etsa kapa ho li khaola ho feta tse ling. Ke habohlokoa ho ba le kutloisiso e feletseng ea "mosebetsi" oa motsoako o mong le o mong, hobane o na le thepa e fapaneng joalo.

Tsena li fumaneha liindastering tse fapaneng, ho kenyeletsoa likoloi, tsa metsing, tsa kaho le tsa elektroniki.

Leha ho le joalo, ho seha le ho sila aluminium ka katleho le ka katleho ho ka ba thata ka mabaka a 'maloa. Aluminium ke tšepe e bonolo e nang le ntlha e tlaase ea ho qhibiliha ho feta lisebelisoa tse ling tse kang tšepe. Litšobotsi tsena li ka lebisa ho ho kenya, ho phunya kapa ho fifala ha mocheso ha ho seha le ho sila thepa.

Aluminium e bonolo ka tlhaho mme ho ka ba thata ho sebetsa ka eona. Ha e le hantle, e ka 'na ea theha sekontiri sa gummy ha se khaola kapa se etsoa ka mochine. Sena ke hobane aluminium e na le mocheso o batlang o le tlase oa ho qhibiliha. Thempereichara ena e tlase hoo hangata e ka kopanang le moeli oa ho itšeha ka lebaka la mocheso oa khohlano.

Ha ho na sebaka sa boiphihlelo ha ho tluoa tabeng ea ho sebetsa le aluminium. Mohlala, 2024 ha e thata haholo ho sebetsa le eona, empa ho batla ho le thata ho e etsa. Alloy e 'ngoe le e' ngoe e na le thepa e fanang ka melemo lits'ebetsong tse ling empa e ka ba bofokoli ho tse ling.

HO KHETHA SEHLAHISO SE LOKELANG HO ALUMINIUM

Mohlomong ntho ea bohlokoa ka ho fetisisa eo u ka e nahanang ka machining ea aluminium ke setsebi sa machini. Ho utloisisa thepa ea aluminium ho bohlokoa empa ho joalo le ka ho khetha lisebelisoa tse nepahetseng le ho tseba ho beha liparamente bakeng sa ts'ebetso ea machining. Leha ho na le mekhoa ea machining ea CNC, motho o tlameha ho nahanela lintho tse ngata kapa u ka qetella u e-na le likhechana tse ngata, 'me sena se ka u amoha phaello leha e le efe eo u e fumanang mosebetsing.

Ho na le lisebelisoa le lihlahisoa tse ngata tse fumanehang bakeng sa ho seha, ho sila le ho qeta aluminium, e 'ngoe le e' ngoe e na le melemo le bofokoli. Ho etsa khetho e nepahetseng bakeng sa kopo ho ka thusa lik'hamphani ho fumana boleng bo betere, polokeho le tlhahiso, ha ho ntse ho fokotsa litšenyehelo tsa nako le basebetsi.

Ha o etsa machining aluminium, o hloka lebelo le phahameng haholo la ho itšeha ho fumana litholoana tse ntle. Ho feta moo, likarolo tsa ho itšeha li tlameha ho ba thata le tse bohale haholo. Mofuta ona oa lisebelisoa tse khethehileng o ka emela letsete le leholo lebenkeleng la mochini ka tekanyetso e lekanyelitsoeng. Litšenyehelo tsena li etsa hore ho be bohlale ho itšetleha ka setsebi sa machining sa aluminium bakeng sa merero ea hau.

Tlhahlobo le tharollo ea mathata a lerata le sa tloaelehang

-

Haeba ho na le molumo o sa tloaelehang ha lehare la sakha le seha aluminium, ho ka etsahala hore lehare la sakha le holofale hanyenyane ka lebaka la mabaka a ka ntle kapa matla a ka ntle a feteletseng, kahoo a tsosa temoso.

-

Tharollo: Lekola lehare la sakha ea carbide hape.

-

Tsela e ka sehloohong ea ho hlakola mochini oa mochini oa ho itšeha oa aluminium e kholo haholo, e bakang ho tlola kapa ho kheloha.

-

Tharollo: Emisa lisebelisoa 'me u hlahlobe ho bona hore na ho kenngoa ho nepahetse.

-

Ho na le lintho tse sa tloaelehang botlaaseng ba lehare la sakha, tse kang mapetsong, ho thibela le ho sotha ha mela / masoba a khutsitseng, li-attachments tse nang le sebōpeho se khethehileng, le lintho tse ling ntle le lisebelisoa tsa ho itšeha tse kopaneng nakong ea ho itšeha.

-

Tharollo: Hlalosa bothata pele 'me u bo rarolle ka nepo u ipapisitse le lisosa tse fapaneng.

Lerata le sa tloaelehang la lehare la sakha le bakoang ke ho fepa ka mokhoa o sa tloaelehang

-

Sesosa se tloaelehileng sa bothata bona ke ho thella ha lehare la carbide saw.

-

Tharollo: Lokisa lehare la sakha

-

Mokotla o ka sehloohong oa mochine oa ho itšeha oa aluminium o khomaretsoe

-

Tharollo: Fetola seluloana ho latela maemo a sebele

-

Lithako tsa tšepe ka mor'a ho cheka li koetsoe bohareng ba tsela ea ho sakha kapa ka pel'a thepa.

-

Tharollo: Hloekisa litšepe ka mor'a ho sakha ka nako

Sesepa sa sawed se na le sebopeho kapa li-burrs tse feteletseng.

-

Hangata boemo bona bo bakoa ke ho tšoaroa ka mokhoa o sa lokelang ha lehare la carbide ka boeona kapa lehare la saw le hloka ho nkeloa sebaka, mohlala: phello ea matrix ha e tšoanelehe, joalo-joalo.

-

Tharollo: Tlosa lehare la sakha kapa u tsosolose lehare la sakha

-

Ho sila ka mahlakoreng ho sa khotsofatseng ha likarolo tsa sawtooth ho fella ka ho se nepahale ho lekaneng.

-

Tharollo: Tlosa lehare la sakha kapa u le khutlisetse ho moetsi hore le tle le siloe hape.

-

Carbide chip e lahlehetsoe ke meno kapa e khomaretsoe ke lithapo tsa tšepe.

-

Tharollo: Haeba meno a lahleha, lehare la sakha le tlameha ho nkeloa sebaka ebe le khutlisetsoa ho moetsi hore le nkeloe sebaka. Haeba e le lithapo tsa tšepe, li hloekise feela.

LIEKETSENG QETELA

Hobane aluminium e bonolo haholo ebile e sa tšoarele ho feta tšepe - ebile e theko e boima - ke habohlokoa ho ela hloko ha u khaola, u sila kapa u qeta thepa. Hopola hore aluminium e ka senyeha habonolo ka litloaelo tse mabifi ho feta tekano. Hangata batho ba lekanya hore na ho etsoa mosebetsi o mongata hakae ka litlhase tseo ba li bonang. Hopola, aluminium ea ho itšeha le ho sila ha e hlahise litlhase, kahoo ho ka ba thata le ho feta ho tseba ha sehlahisoa se sa sebetse kamoo se lokelang. Sheba sehlahisoa ka mor'a ho khaola le ho sila 'me u shebe li-deposit tse kholo tsa aluminium, u ele hloko ka hloko boholo ba thepa e tlosoa. Ho sebelisa khatello e nepahetseng le ho fokotsa mocheso o hlahisoang ts'ebetsong ho thusa ho rarolla mathata a hlahisoang ha ho sebetsa le aluminium.

Ho bohlokoa hape ho khetha sehlahisoa se nepahetseng bakeng sa ts'ebeliso. Batla lihlahisoa tsa boleng bo holimo, tse se nang litšila tse etselitsoeng ho sebelisoa ka aluminium. Sehlahisoa se nepahetseng se kopantsoeng le mekhoa e metle ka ho fetisisa se ka thusa ho hlahisa litholoana tsa boleng bo holimo, ha se ntse se fokotsa nako le chelete e sebelisoang ho sebetsa bocha le lisebelisoa tse lahliloeng.

Hobaneng U Khetha HERO Aluminium alloy cut blade?

-

JAPANE E FUMANA DAMPING KHOMANE -

Ho sisinyeha le ho fokotsa lerata, lisebelisoa tsa ts'ireletso. -

Sealantis e hanyetsanang le mocheso o phahameng oa Japane e tlatsitsoeng ho eketsa mokelikeli oa metsi, ho fokotsa ho sisinyeha le khohlano ea lehare, le ho lelefatsa bophelo ba lehare la sakha. -

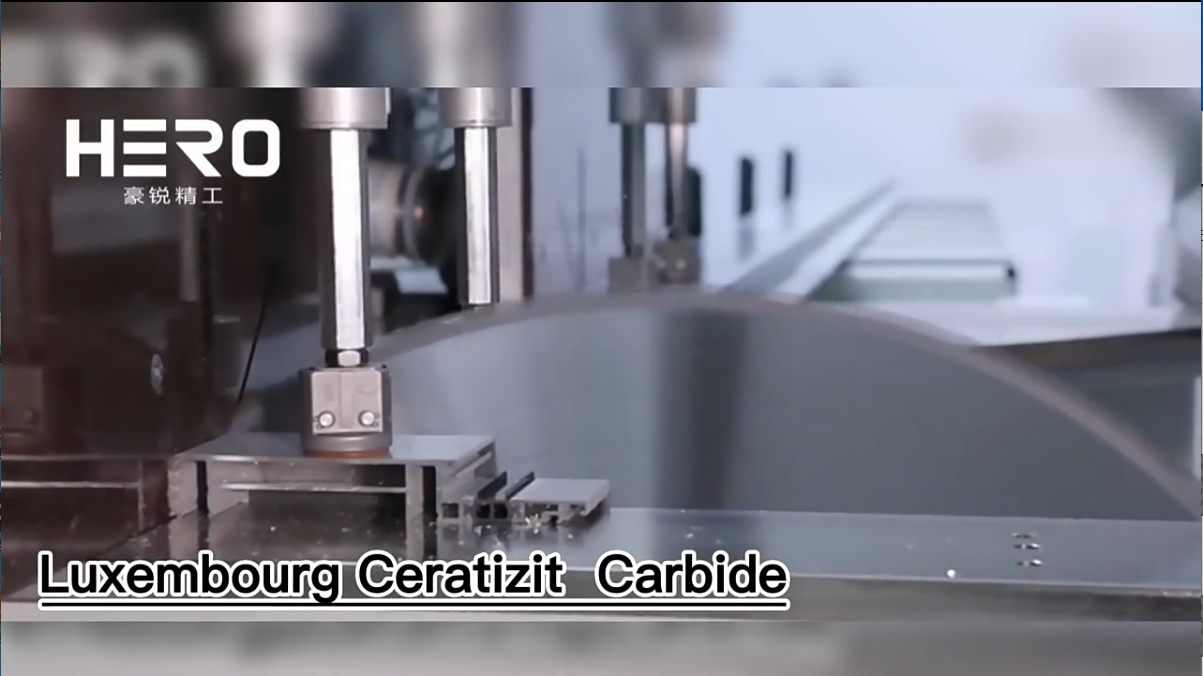

LUXEMBURG CERATIZIT MOKHALE

Carbide ea mantlha ea CARBIDECERATlZIT, ea boleng bo holimo ea Lefatše, e thata ebile e tšoarella nako e telele.

Re sebelisa CERATIZIT NANO-grade carbide,HRA95 °. Transverse rupture power fihla ho 2400Pa,'me re ntlafatsa khanyetso ea carbide ea corrosion le oxidation.The carbide superior durability and stability better for particle board,MDF cutting, Lifetime is more than 30% bapisoa le common industrial blade saw.

Kopo:

-

Mefuta eohle ea aluminium, aluminium ea profil, aluminium e tiileng, aluminium e se nang letho. -

Mochini: Saha e habeli, miter saha, sakha e nkehang.

Nako ea poso: Feb-27-2024

TCT Saw Blade

TCT Saw Blade MOHALE Sizing Saw Blade

MOHALE Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw MOHALE Ho Koanya Saw Blade

MOHALE Ho Koanya Saw Blade MOHALE Sefate se Tiileng Saw Blade

MOHALE Sefate se Tiileng Saw Blade MOHALE Aluminium Saw

MOHALE Aluminium Saw Grooving Saw

Grooving Saw Boemo ba tšepe bo bone

Boemo ba tšepe bo bone Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminium Saw

PCD Aluminium Saw Cold Saw bakeng sa Tšepe

Cold Saw bakeng sa Tšepe Cold Saw Blade ea Ferrous Metal

Cold Saw Blade ea Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Li-Dowel Drill Bits

Li-Dowel Drill Bits Ka li-Drill Bits

Ka li-Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Lisebelisoa tsa router

Lisebelisoa tsa router Likotoana tse otlolohileng

Likotoana tse otlolohileng Likotoana tse telele tse otlolohileng

Likotoana tse telele tse otlolohileng Li-bits tse otlolohileng tsa TCT

Li-bits tse otlolohileng tsa TCT Li-Bits tsa M16 tse otlolohileng

Li-Bits tsa M16 tse otlolohileng TCT X Likotoana tse otlolohileng

TCT X Likotoana tse otlolohileng 45 Degree Chamfer Bit

45 Degree Chamfer Bit Ho betla Bit

Ho betla Bit Corner Round Bit

Corner Round Bit Lisebelisoa tsa router tsa PCD

Lisebelisoa tsa router tsa PCD Lisebelisoa tsa Edge Banding

Lisebelisoa tsa Edge Banding TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Lisebelisoa le Lisebelisoa tse ling

Lisebelisoa le Lisebelisoa tse ling Li-adapter tsa ho cheka

Li-adapter tsa ho cheka Drill Chucks

Drill Chucks Lebili la Lehlabathe la Diamond

Lebili la Lehlabathe la Diamond Lithipa tsa Planer

Lithipa tsa Planer