Ziziphi iingxaki zokusika i-aluminiyam?

I-alloy ye-Alu ibhekisela "kwizinto ezidibeneyo" ezibandakanya isinyithi se-aluminium kunye nezinye izinto zokuphucula iimpawu zokusebenza. Ezinye izinto ezininzi ziquka ubhedu, isilicon ye-magnesium okanye i-zinc, ukukhankanya nje ezimbalwa.

Iialloyi ze-aluminiyam zineepropati ezikhethekileyo ezibandakanya ukumelana nokuhlwa okungcono, ukomelela okuphuculweyo kunye nokuqina, ukukhankanya nje ezimbalwa.

Ialuminiyam ifumaneka kwinani leengxubevange ezahlukeneyo kwaye uthotho ngalunye lunokuba nomsindo ohlukeneyo onokukhetha kuwo. Ngenxa yoko, ezinye i-alloys zinokuba lula kakhulu ukuguba, ukubumba okanye ukusika kunezinye. Kubalulekile ukuba ube nokuqonda okupheleleyo "kokusebenza" kwe-alloy nganye, kuba baneempawu ezahlukeneyo.

Oku kusetyenziswa kuluhlu olubanzi lwemizi-mveliso, kubandakanywa iimoto, zaselwandle, ezokwakha kunye nezombane.

Nangona kunjalo, ukusika kunye nokugaya i-aluminium ngokufanelekileyo nangokufanelekileyo kunokuba ngumngeni ngenxa yezizathu ezininzi. I-Aluminiyam yintsimbi ethambileyo enendawo ephantsi yokunyibilika kunezinye izinto, njengentsimbi. Ezi mpawu zingakhokelela ekulayisheni, ekugubungeleni okanye ekutshintsheni ubushushu xa usika kunye nokugaya izinto.

I-aluminiyam ithambile ngokwendalo kwaye kunokuba nzima ukusebenza nayo. Ngapha koko, inokwenza i-bummy buildup xa isikiwe okanye isenziwa ngoomatshini. Oku kungenxa yokuba i-aluminiyam inobushushu obuphantsi bokunyibilika. Eli qondo lobushushu liphantsi ngokwaneleyo kangangokuba liya kuhlala lidibanisa kwincam yokusika ngenxa yobushushu bokungqubana.

Akukho nto ithatha indawo yamava xa kuziwa ekusebenzeni nge-aluminium. Umzekelo, i-2024 ayinzima kakhulu ukusebenza nayo, kodwa phantse akunakwenzeka ukuyidibanisa. I-alloy nganye ineepropati ezinika uncedo kwezinye izicelo kodwa inokuba yinto engeloncedo kwezinye.

UKUKHETHA IMVELISO EFANELEKILEYO YEALUMINIUM

Mhlawumbi eyona nto ibalulekileyo ekufuneka iqwalaselwe ngomatshini we-aluminium ngumachini. Ukuqonda iipropathi ze-aluminium kubalulekile kodwa ke ukukhetha izixhobo ezifanelekileyo kunye nokwazi ukuseta iiparamitha zenkqubo yomatshini. Nokuba kukho iindlela zobuchwephesha be-CNC, umntu kufuneka athathele ingqalelo izinto ezininzi okanye ungaphela sele unento eninzi yenkunkuma, kwaye oku kunokususa nayiphi na inzuzo oyenzayo emsebenzini.

Kukho izixhobo ezininzi kunye neemveliso ezikhoyo zokusika, ukugaya kunye nokugqiba i-aluminium, nganye inenzuzo kunye nokungonakali. Ukwenza ukhetho olufanelekileyo lwesicelo kunokunceda iinkampani zifumane umgangatho ongcono, ukhuseleko, kunye nemveliso, ngelixa zinciphisa ixesha lokuphumla kunye neendleko zabasebenzi.

Xa usenza i-aluminium, udinga isantya esiphezulu kakhulu sokusika ukuze ufumane iziphumo ezilungileyo. Ukongeza, imiphetho yokusika kufuneka ibenzima kwaye ibukhali kakhulu. Olu hlobo lwezixhobo ezikhethekileyo lunokumela utyalo-mali olukhulu kwivenkile yoomatshini kuhlahlo lwabiwo-mali olulinganiselweyo. Ezi ndleko zenza kube bubulumko ukuthembela kwingcali yomatshini we-aluminium kwiiprojekthi zakho.

Uhlalutyo kunye nezisombululo kwiingxaki ngengxolo engaqhelekanga

-

Ukuba kukho isandi esingaqhelekanga xa i-saw blade isika i-aluminiyam, kunokwenzeka ukuba i-saw blade ikhubazeke kancinane ngenxa yezinto zangaphandle okanye amandla amaninzi angaphandle, ngaloo ndlela ibangela isilumkiso.

-

Isisombululo: Hlaziya i-carbide saw blade.

-

I-shaft ephambili yokucoca umatshini wokusika i-aluminium inkulu kakhulu, ibangela ukutsiba okanye ukuphambuka.

-

Isisombululo: Misa izixhobo kwaye ujonge ukujonga ukuba ukufakela kulungile.

-

Kukho izinto ezingaqhelekanga kwisiseko se-saw blade, njengokuqhekeka, ukuvaleka kunye nokuphazamiseka kwemigca ye-silencer / imingxuma, iziqhotyoshelwano ezikhethekileyo, kunye nezinye izinto ngaphandle kwezinto zokusika ezidibene nazo ngexesha lokusika.

-

Isisombululo: Qwalasela ingxaki kuqala kwaye uyisingathe ngokufanelekileyo ngokusekelwe kwizizathu ezahlukeneyo.

Ingxolo engaqhelekanga yeblade yesarha ebangelwa kukutya okungaqhelekanga

-

Unobangela oqhelekileyo wale ngxaki kukutyibilika kwe-carbide saw blade.

-

Isisombululo: Lungisa iblade yesarha

-

I-shaft ephambili yomatshini wokusika i-aluminium ibambekile

-

Isisombululo: Lungisa i-spindle ngokweyona meko

-

Iifayile zentsimbi emva kokubona zivaliwe phakathi kwendlela yokubona okanye phambi kwezinto eziphathekayo.

-

Isisombululo: Coca iifayili zentsimbi emva kokusarha kwangethuba

I-workpiece yesarha inokwakheka okanye i-burrs egqithisileyo.

-

Le meko idla ngokubangelwa ukuphathwa ngokungafanelekanga kwe-carbide saw blade ngokwayo okanye i-saw blade idinga ukutshintshwa, umzekelo: umphumo we-matrix awufanelekanga, njl.

-

Isisombululo: Faka enye indawo yeblade yesarha okanye uhlengahlengise iblade yesarha

-

Ukunganeliseki kwecala lokusila kwamalungu e-sawtooth kubangela ukuchaneka okwaneleyo.

-

Isisombululo: Faka enye indawo yeblade yesarha okanye uyibuyisele kumvelisi ukuze iphinde igaywe.

-

I-carbide chip ilahlekelwe ngamazinyo okanye ibambelele kwiifayili zentsimbi.

-

Isisombululo: Ukuba amazinyo alahlekile, iblade yesarha kufuneka itshintshwe ize ibuyiselwe kumenzi wayo ukuze ifakwe endaweni yayo. Ukuba ziifayile zentsimbi, zicoce nje.

IINGCINGA ZOKUGQIBELA

Ngenxa yokuba i-aluminiyam ithambile kakhulu kwaye ixolela kakhulu kunentsimbi - kwaye ibiza kakhulu - kubalulekile ukuhlawula ingqalelo xa usika, ukugaya okanye ukugqiba izinto. Khumbula ukuba ialuminiyam ingonakaliswa lula ngezenzo ezindlongondlongo ngokugqithisileyo. Abantu badla ngokujonga ukuba mngakanani umsebenzi owenziwayo ngeentlantsi abazibonayo. Khumbula, ukusika kunye nokusila i-aluminiyam ayivelisi iintlantsi, ngoko ke kunokuba nzima ukuxela xa imveliso ingasebenzi ngendlela ebekufanele ngayo. Khangela imveliso emva kokusika kunye nokugaya kwaye ujonge iidiphozithi ezinkulu ze-aluminium, ubeke ingqalelo ngokukhawuleza kwisixa sezinto ezisuswayo. Ukusebenzisa uxinzelelo olufanelekileyo kunye nokunciphisa ukushisa okwenziwa kwinkqubo kunceda ukujongana nemingeni evezwayo xa usebenza nge-aluminium.

Kwakhona kubalulekile ukukhetha imveliso efanelekileyo kwisicelo. Jonga umgangatho ophezulu, iimveliso ezingenangcoliso ezilungiselelwe ukusetyenziswa nge-aluminiyam. Imveliso efanelekileyo edityaniswe nezona ndlela ziphambili zokuziphatha zinokunceda ukuvelisa iziphumo ezisemgangathweni, ngelixa zinciphisa ixesha kunye nemali echithwe ekusebenzeni ngokutsha kunye nezinto ezilahliweyo.

Kutheni Khetha i-HERO Aluminiyam ingxubevange yokusika isarha yesarha?

-

IJAPAN ITHETHA IGLUE YEDAMPING -

Ukungcangcazela kunye nokunciphisa ingxolo, izixhobo zokukhusela. -

I-sealantis yaseJapan yoqobo yokumelana nobushushu obuphezulu izaliswe ukunyusa i-coefficient yokumanzisa, ukunciphisa ukungcangcazela kunye nokukhuhlana kweblade, kwaye yandise ubomi beblade yesarha.Ngaxeshanye, inokuphepha ngokufanelekileyo i-resonance kwaye yandise ubomi benkonzo yesixhobo.Ingxolo elinganisiweyo iyancipha nge-4 -6 decibels, inciphisa ngokufanelekileyo i-pollution. -

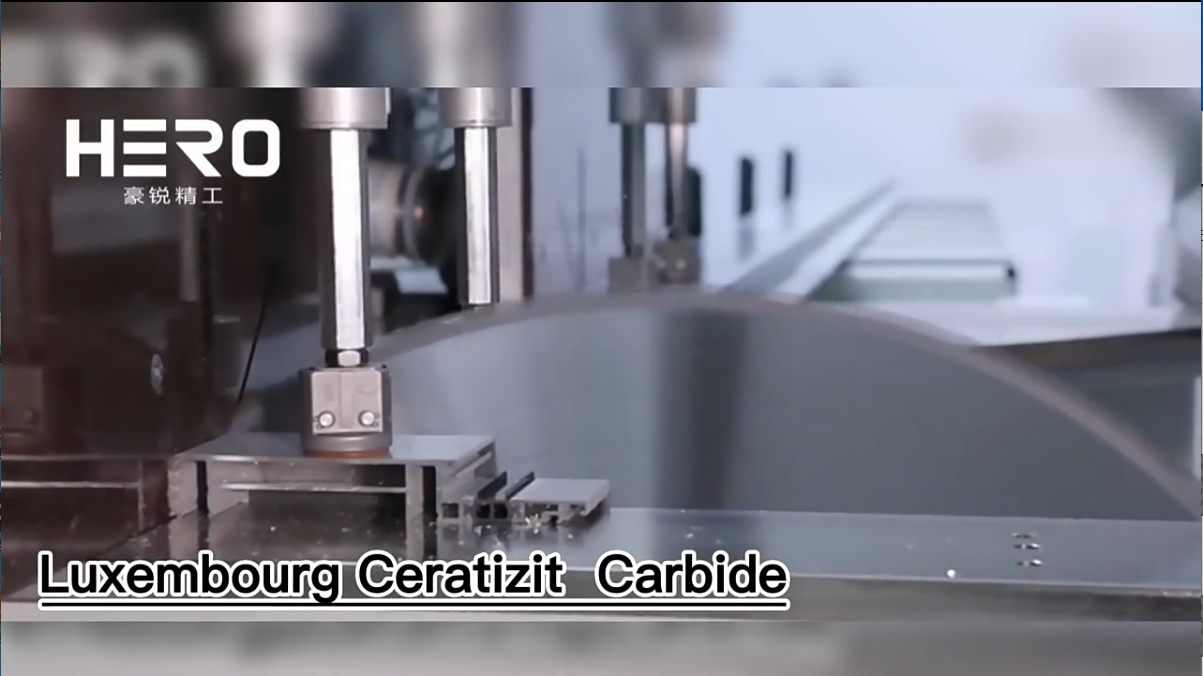

LUXEMBURG CERATIZIT ORIGINAL

I-CARBIDECERATlZIT ye-carbide yoqobo, umgangatho ophezulu wehlabathi, Unzima kwaye uhlala ixesha elide.

Sisebenzisa i-CERATIZIT NANO-grade carbide, i-HRA95 °. Amandla okuqhawula afikelela kwi-2400Pa, kwaye siphucule ukuxhathisa kwe-carbide ye-corrosion kunye ne-oxidation.I-carbide ukuqina okuphezulu kunye nokuqina okungcono kwibhodi yamasuntswana, ukusika kwe-MDF, Ubomi bungaphezulu kwe-30% xa kuthelekiswa neklasi yesiqhelo ye-industrial blade.

Isicelo:

-

Zonke iintlobo ze-aluminiyam, i-aluminium yeprofayili, i-aluminium eqinile, i-aluminiyam engenanto. -

Umtshini:Isarha yonkontsho ephindwe kabini, isarha yokutyibiliza, isarha ephathwayo.

Ixesha lokuposa: Feb-27-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Ubungakanani Saw

HERO Panel Ubungakanani Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade IQHAWE LOKUQHUBEKA kweenkuni zabona iBlade

IQHAWE LOKUQHUBEKA kweenkuni zabona iBlade HERO Aluminiyam Saw

HERO Aluminiyam Saw I-Grooving Saw

I-Grooving Saw Iprofayile yentsimbi yabona

Iprofayile yentsimbi yabona Edge Bander wabona

Edge Bander wabona Saw Acrylic

Saw Acrylic PCD Saw Blade

PCD Saw Blade PCD Ubungakanani beSaw Blade

PCD Ubungakanani beSaw Blade PCD Panel Ubungakanani Saw

PCD Panel Ubungakanani Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminium Saw

PCD Aluminium Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Metal Ferrous

Cold Saw Blade for Metal Ferrous Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Umtshini weSaw obandayo

Umtshini weSaw obandayo Drill Bits

Drill Bits Amasuntswana eDowel Drill

Amasuntswana eDowel Drill Ngokusebenzisa i-Drill Bits

Ngokusebenzisa i-Drill Bits Amasuntswana e-Hinge Drill

Amasuntswana e-Hinge Drill TCT Inyathelo Drill Bits

TCT Inyathelo Drill Bits HSS Drill Bits / Mortise Bits

HSS Drill Bits / Mortise Bits Amasuntswana eRouter

Amasuntswana eRouter Amasuntswana aNgqo

Amasuntswana aNgqo Amasuntswana amade athe ngqo

Amasuntswana amade athe ngqo TCT Amasuntswana aNgqo

TCT Amasuntswana aNgqo M16 Amasuntswana aNgqo

M16 Amasuntswana aNgqo TCT X Amasuntswana aNgqo

TCT X Amasuntswana aNgqo 45 Isidanga seChamfer Bit

45 Isidanga seChamfer Bit Ukukrola Bit

Ukukrola Bit Bit yeKona

Bit yeKona Amasuntswana omzila wePCD

Amasuntswana omzila wePCD Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander wabona

Edge Bander wabona I-PCD Fine Trimming Cutter

I-PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Ezinye izixhobo kunye nezixhobo

Ezinye izixhobo kunye nezixhobo Drill Adapter

Drill Adapter Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Iimela zokucwangcisa

Iimela zokucwangcisa