Kulesi sihloko, sizobuyekeza uhlobo lwamazinyo abalulekile mayelana nama-saha ayindilinga angakusiza ukusika izinhlobo ezahlukene zokhuni kalula nangokunemba. Noma ngabe udinga i-blade yokuklebhula, ukunqamula, noma ukusikeka kwenhlanganisela, sine-blade yakho. Sizophinde sikunikeze amathiphu awusizo okuthi ungakhetha kanjani i-blade efanele yephrojekthi yakho nokuthi ungayigcina kanjani ukuze isebenze kahle.

Okuqukethwe

- Ama-sawblades ayindilinga

- Izimo ezijwayelekile nezisetshenziswayo zamazinyo

- Ithonya lezinkuni njengento eluhlaza neyisisekelo kumathuluzi okusika

- Indlela yokukhetha i-saw blade efanele

Ama-saw blades ayindilinga

Ama-sawblade ayindilinga angamathuluzi okuqhubekela phambili okusika ipulasitiki nokhuni.

Aqukethe ipuleti lesaha elenziwe ngedayimane le-polycrystalline noma i-tungsten carbide.

amazinyo abomvu ngaphandle kwayo. Basetshenziswa ukuze bahlukanise ama-workpieces.

Ukuze Umgomo uwukwenza ububanzi bokusika bube buncane ngangokunokwenzeka ngenkathi kunciphisa ukulahlekelwa kokusika kanye nezingcindezi zokusika. Ngokuphambene, ukusikeka okuqondile akuthintwa Izikolo zidinga izinga elithile lokuzinza kwe-blade, okuyinto edinga nakanjani imvume.

< =”font-family: 'times new roman', izikhathi; usayizi wefonti: medium;”>phakathi kweblade yesaha nobubanzi bokusika.ijometri kanye nempahla yendawo yokusebenza, amazinyo esaha ngokwejometri kanye nokuma. Ama-engeli amahle wokusika ngokuvamile asetshenziselwa ukunciphisa amandla okusika. Okwezinto zokusebenza ezinezindonga ezincane, isb

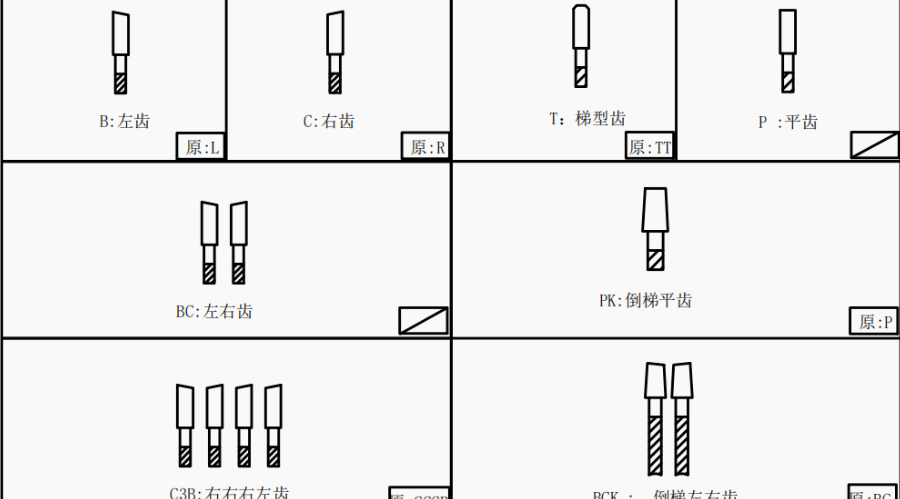

Izimo ezijwayelekile nezisetshenziswayo zamazinyo

Ukugcina isaha lingabambeki kumaphrofayili angenalutho, ama-engeli wokusika ayadingeka. Inani lamazinyo linqunywa izindinganiso zekhwalithi ezisikiwe. Umthetho ojwayelekile wukuthi uma kukhona amazinyo engeziwe, izinga lokusikwa likhulu, futhi amazinyo ambalwa akhona, ukusika kwesaha kubushelelezi.

Ukuhlukaniswa kwamafomu amazinyo ajwayelekile kanye nezicelo:

| Izinyo shape | Isicelo |

| Ifulethi FZ | Ukhuni oluqinile, eceleni naphakathi kokusanhlamvu. |

| Enye, i-WZ enhle | Ukhuni oluqinile phakathi naphakathi kokusanhlamvu kanye nokunamathiselwe, imikhiqizo yokhuni.engaxutshiwe, ipulasitiki eboshwe noma eyenziwe ngevene, i-plywood, i-multiplex, izinto eziyinhlanganisela, impahla elaminate |

| Okunye, negativeWZ | Ukhuni oluqinile kuwo wonke okusanhlamvu, amaphrofayili epulasitiki angenalutho, amaphrofayili ensimbi angeyona ayoni namashubhu. |

| Isikwele/trapezoidal, positive FZ/TR | Imikhiqizo yokhuni, engagqokisiwe, enamapulasitiki enziwe ngepulasitiki noma enziwe ngevene, amaphrofayili ensimbi angeyona ayoni namashubhu, izinsimbi ezingenayo ayoni, amaphaneli amasemishi e-AI-PU, amaphrofayili epulasitiki angenalutho, amapulasitiki e-polymer (i-Corian, i-Varicor njll.) |

| Isikwele/trapezoidal, i-negative FZ/TR | Amaphrofayli namapayipi ensimbi engeyona insimbi, amaphrofayili angenalutho epulasitiki, amaphaneli amasemishi e-AI-PU. |

| Flat, bevelledES | Amasaha emishini yemboni yezokwakha. |

| I-V/inhlabathi engenalutho HZ/DZ ehlanekezelwe | Imikhiqizo yokhuni, embozwe ngepulasitiki futhi enwetshiwe, imichilo yephrofayili eboshiwe (amabhodi esiketi). |

Lezi yizinhlobo eziyisikhombisa zamazinyo ezibalulekile mayelana namasaha ayindilinga.

Ithonya lezinkuni njengento eluhlaza neyisisekelo kumathuluzi okusika

Kodwa-ke, ekusetshenzisweni kwangempela, ngoba izinto zokusika zihlukile, futhi ngesikhathi esifanayo isiqondiso sokusika sihlukile. Umphumela wokusika kanye nempilo yamathuluzi nakho kuzothinteka.

Nakuba i-softwood ne-conifer, ukhuni oluqinile kanye ne-broadleaf ngokuvamile kuqhathaniswa, kunezinye izinto ezingaphandle, njenge-yew, i-hardwood, ne-alder, birch, lime, poplar, ne-willow, okuyizinkuni ezithambile.

Ukuminyana, amandla, ukunwebeka, nobulukhuni yiziguquko ezibalulekile ekucubunguleni nasekukhetheni amathuluzi. Ngenxa yalokho, ukuhlukanisa ukhuni oluqinile kanye ne-softwood kubalulekile ngoba kunikeza ireferensi ephelele yalezi zimfanelo.

Lapho ufeza amasu okucubungula izinkuni kanye nokubaza, kubalulekile ukuqaphela ukuthi izinkuni ziyizinto ezihlukene zesakhiwo kanye nekhwalithi. Lokhu kuboniswa ikakhulukazi izindandatho ezikhulayo zokhuni lwe-coniferous. Ubulukhuni buhluka kakhulu phakathi kwe- earlywood ne latewood. Lezi zici kufanele zicatshangelwe ngesikhathi sokwenza izinkuni kanye nezinto zokusika, i-geometry yokusika kanye nemingcele yokucubungula kufanele ilungiswe ngokufanele. Lapho usebenza ngezinhlobo ezahlukene zezinkuni, ukuyekethisa kuyadingeka. Kuye ngezici namapharamitha wento oyicubungulayo, ngisho nokuthi zingaki izinhlobo zezinto, yenza izinguquko ezifanele.

Futhi ngezimfanelo eziningi zobuchwepheshe bokusika, ukuminyana kwenqwaba kuyisici esinqumayo. Ukuminyana kwenqwaba isilinganiso sesisindo nevolumu (okuhlanganisa zonke izinhlayiya). Ngokuya ngohlobo lwezinkuni, ukuminyana kwenqwaba kuvame ukusuka ku-100 kg/m3 kuya ku-1200 kg/m3.

Ezinye izici ezithinta ukugqoka onqenqemeni ukwakheka kwezinkuni, njengama-tannins noma ama-silicate inclusions.

Nazi ezinye izingxenye zamakhemikhali ezivamile ezikhona ngokhuni.

Ama-tannins emvelo, njengalawo atholakala ku-oki, abangela ukuguga kwamakhemikhali onqenqemeni lokusika lwethuluzi.

Lokhu kuyiqiniso ikakhulukazi uma umswakama wokhuni uphezulu.

I-silicate inclusions, njengaleyo etholakala emahlathini ashisayo, i-teak noma i-mahogany, imuncwa phansi kanye nezakhamzimba. Ibe isicwebezela ezitsheni.

Bandisa ukuguga kwe-abrasive onqenqemeni lokusika.

Umehluko wokuminyana phakathi kwe-earningwood ne-latewood ngokuvamile ubalulekile

Ngokuvamile uphawu lokuqhekeka kwangaphambili okuqinile kanye nokuthambekela kokuhlukana ngesikhathi sokucubungula (isb. Uphayini obomvu waseYurophu). Ngesikhathi esifanayo umbala wokhuni ungahluka.

Ukwanda kwesidingo sokhuni emhlabeni wonke kungenxa yokuthi ziyanda izihlahla ezitshalwa zibe amahlathi. Lawa okuthiwa amahlathi atshalwayo ngokuvamile akhula ngokushesha

izinhlobo ezifana ne-radiata pine, eucalyptus kanye ne-poplar. Uma kuqhathaniswa nezitshalo ezikhula emahlathini emvelo, lezi zitshalo zinezindandatho zonyaka eziqinile futhi ziminyene futhi

amandla aphansi. Ngenxa yokuba sengozini enkulu yokuqhekeka kweziqu kanye nokuhlukaniswa kwe-fiber, ngezinye izikhathi ukuvunwa kwamapulangwe epulazini kungaba inselele yangempela.

Kudinga amasu okucubungula akhethekile kanye nezixazululo ezikhethekile zamathuluzi.

Indlela yokukhetha i-saw blade efanele

Khona-ke ngemva kokuqonda okuyisisekelo okungenhla, umehluko ngokhuni , umehluko ekubunjweni kwezinyo.

Isinyathelo esilandelayo ukuthi ungayikhetha kanjani i-saw blade efanele.Kulesi sihloko, sizokukhombisa ukuthi ungayenza kanjani ngezindlela eziningi.

I.Isisekelo sokukhetha ama-blade asaha ayindilinga

Ngokusho kwe-sawing material properties ukuhlukaniswa

1,Si-olidWood:Cukusika i-ross,Lukusika i-ongitudinal.

I-cross-cutting idinga ukusika i-fiber yokhuni, indawo esikiwe idinga isicaba, ayikwazi ukuba nezimpawu zommese, futhi ayikwazi ukuba ne-burr, ukuthi i-saw blade esetshenziswa ububanzi obungaphandle10 amayintshi noma 12 amayintshinenani lamazinyo kufanele libe phakathiAmazinyo angama-60 kuye kwayi-120, lapho ukusetshenziswa kwenani lamazinyo kuncipha, kuba nemishini eyengeziwe. Isivinini sokuphakelayo kufanele sihambe kancane ngokufanayo. I-Longitudinal saw enamazinyo ambalwa, isivinini sokudla sizoshesha, ngakho-ke izidingo zokukhishwa kwe-chip ziphezulu kakhulu, ngakho-ke izidingo ze-saw bladeOD 10 amayintshi noma 12 amayintshingenani lamazinyo phakathiAmazinyo angama-24 nama-40.

2,Amabhodi akhiqiziwe: Ibhodi lokuminyana, ibhodi lezinhlayiyana, i-plywood.

Ukusika kudinga ukucabangela ngokugcwele amandla okusika, kanye nenkinga yokukhishwa kwe-chip, ukusetshenziswa kwama-saw blades ane-diameter yangaphandle10 amayintshi noma 12 amayintshikwamazinyo kufanele kube phakathiAmazinyo angama-60 kuye kwangama-96.

Ngemuva kwemithetho emibili engenhla, ungasebenzisaBC amazinyouma kukhona aukhuni oluqinile, ibhodi elingenaluthongaphandle kwe-veneer kanye nezindinganiso ze-polish ezisikiwe aziphezulu kakhulu. Lapho ukusikaibhodi lezinhlayiyanange-veneer,ipulangwe, ibhodi labantu, nokunye, sebenzisa isaha ngeAmazinyo e-TP. Amazinyo ambalwa, aphansi ukumelana nokusika; lapho amazinyo engeziwe, kukhulu ukumelana nokusika, kodwa indawo yokusika ibushelelezi.

- Isiphetho

Kunezinhlobo eziningi zamasaha ayindilinga asetshenziswa ngendlela ehlukene. Ekusetshenzisweni kwangempela, kufanele kuhlanganiswe nokuthi iyiphi impahla yokusika, esetshenziswayo, ehlanganiswe nomshini. Khetha isimo sezinyo esifanele, ubukhulu obufanele bohlobo oluhambisanayo lwe-saw blade.

Sihlala sikulungele ukukunikeza amathuluzi okusika alungile.

Njengomphakeli wamasaha ayindilinga, sinikezela ngezimpahla zeprimiyamu, iseluleko somkhiqizo, isevisi yobungcweti, kanye nenani elihle nokusekelwa okukhethekile ngemva kokuthengisa!

Ku-https://www.koocut.com/.

Yeqa umkhawulo futhi uqhubekele phambili ngesibindi! Isiqubulo sethu.

Futhi sizozimisela ukuba yisisombululo esihamba phambili sobuchwepheshe bokusika kanye nomhlinzeki wesevisi e-China, esikhathini esizayo sizofaka isandla sethu esikhulu ekukhuthazeni ukukhiqizwa kwamathuluzi okusika asekhaya ekuhlakanipheni okuthuthukile.

Isikhathi sokuthumela: Aug-23-2023

I-TCT Saw Blade

I-TCT Saw Blade IQHAWE Sizing Saw Blade

IQHAWE Sizing Saw Blade I-HERO Panel Sizing Saw

I-HERO Panel Sizing Saw IQHAWE Lokushaya I-Saw Blade

IQHAWE Lokushaya I-Saw Blade IQHAWE Eliqinile Izinkuni Saw Blade

IQHAWE Eliqinile Izinkuni Saw Blade IQHAWE Aluminium Saw

IQHAWE Aluminium Saw I-Grooving Saw

I-Grooving Saw Iphrofayili Yensimbi Yabona

Iphrofayili Yensimbi Yabona I-Edge Bander Saw

I-Edge Bander Saw I-Acrylic Saw

I-Acrylic Saw I-PCD Saw Blade

I-PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade I-PCD Panel Sizing Saw

I-PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade I-PCD Grooving Saw

I-PCD Grooving Saw I-PCD Aluminium Saw

I-PCD Aluminium Saw I-Cold Saw Yensimbi

I-Cold Saw Yensimbi Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal I-Dry Cut Saw Blade ye-Ferrous Metal

I-Dry Cut Saw Blade ye-Ferrous Metal Cold Saw Machine

Cold Saw Machine I-Drill Bits

I-Drill Bits Izingcezu ze-Dowel Drill

Izingcezu ze-Dowel Drill Nge-Drill Bits

Nge-Drill Bits Ama-Hinge Drill Bits

Ama-Hinge Drill Bits TCT Isinyathelo Drill Bits

TCT Isinyathelo Drill Bits HSS Drill Bits/Mortise Bits

HSS Drill Bits/Mortise Bits Ama-router Bits

Ama-router Bits Amabhithi Aqondile

Amabhithi Aqondile Izingcezu Ezinde Eziqondile

Izingcezu Ezinde Eziqondile Amabhithi Aqondile we-TCT

Amabhithi Aqondile we-TCT I-M16 Amabhithi Aqondile

I-M16 Amabhithi Aqondile I-TCT X Amabhithi Aqondile

I-TCT X Amabhithi Aqondile 45 Degree Chamfer Bit

45 Degree Chamfer Bit I-Carving Bit

I-Carving Bit I-Corner Round Bit

I-Corner Round Bit I-PCD Router Bits

I-PCD Router Bits Edge Banding Amathuluzi

Edge Banding Amathuluzi I-TCT Fine Trimming Cutter

I-TCT Fine Trimming Cutter I-TCT Pre Milling Cutter

I-TCT Pre Milling Cutter I-Edge Bander Saw

I-Edge Bander Saw I-PCD Fine Trimming Cutter

I-PCD Fine Trimming Cutter I-PCD Pre Milling Cutter

I-PCD Pre Milling Cutter I-PCD Edge Bander Saw

I-PCD Edge Bander Saw Amanye Amathuluzi Nezesekeli

Amanye Amathuluzi Nezesekeli I-Drill Adapter

I-Drill Adapter Drill Chucks

Drill Chucks Isondo Lesanti Ledayimane

Isondo Lesanti Ledayimane Imimese Yokuhlela

Imimese Yokuhlela