He aha ka pilikia me ka hoʻopaʻa ʻana?

ʻO Edgebanding e pili ana i ke kaʻina hana a me ke kāʻei o nā mea i hoʻohana ʻia no ka hana ʻana i nā ʻoki nani a puni nā ʻaoʻao i pau ʻole o ka plywood, particle board, a i ʻole MDF. Hoʻonui ʻo Edgebanding i ka lōʻihi o nā papahana like ʻole e like me ka cabinetry a me nā countertops, hāʻawi iā lākou i kahi hiʻohiʻona kiʻekiʻe a maikaʻi.

Pono ʻo Edgebanding i ka versatility ma ke ʻano o ka hoʻopili ʻana. ʻO ka mahana o ka lumi, a me ka substrate, pili i ka adhesion. No ka mea, hana ʻia ka edgebanding mai nā mea like ʻole he nui, he mea nui ia e koho i kahi adhesive e hāʻawi i ka versatility a me ka hiki ke hiki ke hoʻopaʻa i nā ʻano substrates.

ʻO ka hoʻoheheʻe wela wela he mea hoʻopili multi-purpose i hoʻohana ʻia i kahi ākea o nā noi a kūpono no ka nani o nā lihi āpau āpau e like me PVC, melamine, ABS, acrylic a me ka lāʻau veneer. He koho maikaʻi loa ka hoʻoheheʻe wela no ka mea hiki ke hoʻoheheʻe hou ʻia, a maʻalahi ke hana pū me.

Eia nō naʻe, inā ʻike maopopo ʻia ka hili ʻana o ke kāpili, ʻaʻole paha i hoʻopau pono ʻia nā mea hana. ʻEkolu mau ʻāpana nui: ʻāpana ʻoki ʻoki ma mua o ka wili ʻana, ʻāpana wili pahu a me ka ʻāpana kaomi.

1. Abnormality i loko o ka pre-milling cutter hapa

-

Inā he kualono ka ʻili o ka papa mua o ka wili a hoʻopili ʻole ʻia ke kāpili, hiki mai nā hemahema e like me ka nui o nā laina kāpili. Ma hope o ka wili mua ʻana iā MDF, e nānā inā palahalaha ka ʻili o ka papa. -

Inā ʻaʻole kūlike ka pā ma mua, ʻo ka hopena e hoʻololi iā ia me kahi ʻoki ʻoki mua.

2. He ʻano ʻē ka ʻāpana huila.

-

Aia paha ke kuhi hewa i ka perpendicularity ma waena o ka huila uhi ʻili a me ka ʻili kumu o ka pā. Hiki iā ʻoe ke hoʻohana i ka ruler square e ana i ka perpendicularity. -

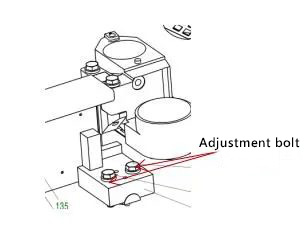

Ināʻoi aku ka nui o ka hewa ma mua o 0.05mm, ua'ōleloʻia e hoʻololi i nā meaʻoki wili a pau. I ka wā i lalo o ka wela o kaʻoihanaʻoihana, ke kiʻekiʻe ka mahana o 180 ° C a hikiʻole ke hoʻopāʻia me nā lima lima. ʻO ke ala maʻalahi loa e nānā ai, ʻo ia ka ʻimi ʻana i kahi ʻāpana MDF, hoʻoponopono i ka nui o ke kāpili i ka liʻiliʻi loa, a ʻike inā ua piʻi a i lalo ka ʻili hope. E hana i nā hoʻololi liʻiliʻi ma ka hoʻoponopono ʻana i nā bolts i hiki ke hoʻopili pono ʻia ka maka hope holoʻokoʻa me ka liʻiliʻi liʻiliʻi o ke kāpili.

3. He 'ano 'ole ka huila kaomi

-

Aia ke koena o nā hōʻailona glue ma ka ʻili o ka huila kaomi, a ʻaʻohe kūlike ka ʻili, kahi e hoʻopilikia maikaʻi ʻia ai. Pono e hoʻomaʻemaʻe i ka manawa, a laila e nānā inā he maʻamau ke kaomi ea a me ka huila kaomi. -

ʻO nā hewa i ka verticality o ka huila paʻi e alakaʻi pū ai i ka sila ʻino ʻole. Eia nō naʻe, pono ʻoe e hōʻoia mua he palahalaha ka ʻili kumu o ka papa ma mua o ka hoʻoponopono ʻana i ka verticality o ka huila paʻi.

ʻO nā kumu maʻamau ʻē aʻe e pili ana i ka maikaʻi o ka bing lihi

1, Pilikia Lako

No ka mea, ʻaʻole hiki i ka ʻenekini o ka mīkini hoʻopaʻa ʻaoʻao a me ke ala ke hui maikaʻi, ʻaʻole paʻa ke ala i ka wā o ka hana ʻana, a laila ʻaʻole kūpono ka ʻaoʻao o ka ʻaoʻao i ka lihi. ʻO ka nele o ke kāpili a i ʻole ka uhi ʻole ʻia ke kumu pinepine ʻia e ke koʻokoʻo kaomi ʻana ʻaʻole i hui maikaʻi me ke kaulahao conveyor. Inā ʻaʻole i hoʻoponopono pono ʻia nā mea hana ʻokiʻoki a me nā mea hana chamfering, ʻaʻole wale e koi i ka hana ʻoi aku ka hana, a paʻakikī ke ʻano o ka ʻoki ʻana.

I ka pōkole, ma muli o ka pae maikaʻi ʻole o ka hoʻokō ʻana i nā mea hana, hoʻoponopono a mālama ʻia, e mau nā pilikia maikaʻi. ʻO ka blunt o nā mea hana ʻoki e pili pono i ka maikaʻi o nā hopena a me ka ʻoki ʻana. ʻO ke kihi ʻokiʻoki i hāʻawi ʻia e nā mea hana ma waena o 0 ~ 30 °, a ʻo ke kihi ʻoki i koho ʻia i ka hana maʻamau he 20 °. E emi ana ka maikaʻi o ka ʻili ma ka ʻaoʻao ʻōpuʻu o ka mea ʻoki.

2, Ka Mea Hana

ʻO ka lāʻau i hana ʻia e ke kanaka e like me ke ʻano o ka mea hana, ʻaʻole hiki i ka ʻae ʻana o ka mānoanoa a me ka palahalaha i nā kūlana. ʻO kēia ka mea e paʻakikī ai ka hoʻonohonoho ʻana i ka mamao mai nā huila kaomi a hiki i ka ʻili o ka conveyor. Inā liʻiliʻi loa ka mamao, e hoʻokaʻawale ʻia nā ʻāpana a me nā mea hana. Inā ʻoi aku ka nui o ka mamao, ʻaʻole e hoʻopili ʻia ka pā, a ʻaʻole hiki ke hoʻopaʻa paʻa ʻia nā ʻāpana me ka lihi.

3, Nā Paʻi Paʻi lihi

Hana ʻia ka nui o nā ʻāpana ʻāpana i ka PVC, hiki ke hoʻopilikia nui ʻia e ke kaiapuni. I ka hoʻoilo, e piʻi aʻe ka paʻakikī o nā paʻi PVC e hoʻemi ai ka pili ʻana o ke kāpili. A ʻo ka lōʻihi o ka mālama ʻana, e ʻelemakule ka ʻili; ʻoi aku ka haʻahaʻa o ka ikaika pili i ke kāpili. No nā pepa i hana ʻia me ka mānoanoa liʻiliʻi, ma muli o ko lākou paʻakikī kiʻekiʻe a me ka mānoanoa haʻahaʻa (e like me 0.3mm), e hoʻopiʻi ʻole ʻia ka ʻoki ʻana, lawa ʻole ka ikaika o ka hoʻopaʻa ʻana, a me ka maikaʻi ʻole o ka ʻoki ʻana. No laila he koʻikoʻi nā pilikia e like me ka ʻōpala nui o nā ʻāpana lihi a me ka nui o ka hana hou ʻana.

4, lumi wela a me ka mīkini wela

Ke haʻahaʻa ka mahana o loko, hele ka mea hana i ka mīkini bing edge, ʻaʻole hiki ke hoʻonui koke ʻia kona mahana, a i ka manawa like, ua maʻalili koke ka mea paʻa i paʻakikī ke hoʻopau i ka hoʻopaʻa ʻana. No laila, pono e hoʻomaluʻia ka mahana o loko ma luna o 15 ° C. Inā pono, hiki ke hoʻomehana muaʻia nā'āpana o ka mīkini banding ma mua o ka hanaʻana (hiki ke hoʻohuiʻia kahi mea hoʻomehana uila i ka hoʻomakaʻana o ke kaʻina hana lihi). I ka manawa like, pono e like a i ʻole ʻoi aku ka kiʻekiʻe o ka wela hōʻike wela o ke koʻokoʻo kaomi gluing ma mua o ka wela i hiki ke hoʻoheheʻe ʻia ka mea hoʻoheheʻe wela.

5, ʻO ka wikiwiki hānai

ʻO ka wikiwiki o ka hānai ʻana i nā mīkini ʻokiʻoki o kēia manawa he 18 ~ 32m / min. Hiki i kekahi mau mīkini kiʻekiʻe kiʻekiʻe ke hiki i 40m / min a i ʻole ke kiʻekiʻe, ʻoiai ʻo ka mīkini paʻi kiʻekiʻe kiʻekiʻe e loaʻa i ka wikiwiki hānai o 4 ~ 9m / min. Hiki ke hoʻololi ʻia ka wikiwiki o ka hānai ʻana i ka mīkini wili lihi e like me ka ikaika o ka lihi. Inā kiʻekiʻe ka wikiwiki o ka hānai ʻana, ʻoiai ʻoi aku ka maikaʻi o ka hana ʻana, haʻahaʻa ka ikaika o ka ʻaoʻao.

Na mākou ke kuleana e hoʻopaʻa pololei i ka band. Akā, pono ʻoe e ʻike, aia nō nā koho e pono ai ʻoe e hana i ka wā e loiloi ai i nā koho banding edge.

No ke aha e koho ai i ka mea ʻoki ʻoki mua HERO?

-

Hiki iā ia ke hana i nā mea like ʻole. ʻO nā mea hana koʻikoʻi he papa density, particle board, multilayer plywood, fiberboard, etc. -

Hana ʻia ka pahi i nā mea daimana i lawe ʻia mai, a aia kahi hiʻohiʻona kūpono o ka hoʻolālā niho me. -

Kūʻokoʻa a nani hoʻi me ka pahu pahu a me ka sponge i loko, hiki ke pale i ka wā o ka lawe ʻana. -

Hoʻopau maikaʻi ia i nā hemahema o ka ʻaʻahu ʻole a me ke koʻikoʻi o ka ʻoki carbide. Hiki iā ia ke hoʻomaikaʻi nui i ka maikaʻi o ke ʻano o ka huahana. Hāʻawi i kahi ola hoʻohana lōʻihi. -

ʻAʻohe ʻeleʻele, ʻaʻohe ʻāpana ʻāpana, hiʻohiʻona maikaʻi o ka hoʻolālā niho, e like me ka ʻenehana hana. -

Loaʻa iā mākou ma mua o 20 mau makahiki o ka ʻike a hāʻawi i nā lawelawe kūʻai mua a ma hope o ke kūʻai aku. -

ʻOi aku ka maikaʻi o ka ʻoki ʻana i nā mea lāʻau i loaʻa nā fibers.

Ka manawa hoʻouna: Mar-01-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Makaʻala ʻike maka

HERO Makaʻala ʻike maka HERO Ike Laau Paa

HERO Ike Laau Paa HERO Aluminum Saw

HERO Aluminum Saw ʻIli ʻO Grooving

ʻIli ʻO Grooving Ike kila kila

Ike kila kila Edge Bander Saw

Edge Bander Saw ʻili ʻili

ʻili ʻili ʻO PCD Saw Blade

ʻO PCD Saw Blade ʻO ka lāʻau ʻili PCD

ʻO ka lāʻau ʻili PCD ʻO ka ʻili ʻili ʻana o ka ʻili ʻana o ka Panel PCD

ʻO ka ʻili ʻili ʻana o ka ʻili ʻana o ka Panel PCD ʻO ka ʻili ʻike PCD

ʻO ka ʻili ʻike PCD ʻIli ʻo PCD Grooving Saw

ʻIli ʻo PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw ʻili anu no ka metala

ʻili anu no ka metala ʻO ka Maka ʻili anu no ka metala ferrous

ʻO ka Maka ʻili anu no ka metala ferrous ʻOki ʻoki ʻoki maloo no ka metala ferrous

ʻOki ʻoki ʻoki maloo no ka metala ferrous Mīkini ʻIli anu

Mīkini ʻIli anu ʻO nā ʻāpana wili

ʻO nā ʻāpana wili Nā Bits Drill Dowel

Nā Bits Drill Dowel Ma o Drill Bits

Ma o Drill Bits ʻO nā ʻāpana Drill Hinnge

ʻO nā ʻāpana Drill Hinnge TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Nā Bits Alaula

Nā Bits Alaula Nā Bit Pololei

Nā Bit Pololei Nā Bit Pololei lōʻihi

Nā Bit Pololei lōʻihi TCT Pololei Bits

TCT Pololei Bits M16 Pololei Bits

M16 Pololei Bits TCT X Pololei Bits

TCT X Pololei Bits 45 Degere Chamfer Bit

45 Degere Chamfer Bit Bit Kalai

Bit Kalai Bit Poe Kihi

Bit Poe Kihi PCD Router Bits

PCD Router Bits Mea Paahana Edge Banding

Mea Paahana Edge Banding ʻOki ʻoki ʻoki maikaʻi ʻo TCT

ʻOki ʻoki ʻoki maikaʻi ʻo TCT TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw ʻOki ʻoki ʻoki maikaʻi PCD

ʻOki ʻoki ʻoki maikaʻi PCD PCD Pre Milling Cutter

PCD Pre Milling Cutter ʻIke ʻo PCD Edge Bander

ʻIke ʻo PCD Edge Bander Nā mea hana a me nā mea hana ʻē aʻe

Nā mea hana a me nā mea hana ʻē aʻe Nā mea hoʻopili wili

Nā mea hoʻopili wili ʻO nā Chucks Drill

ʻO nā Chucks Drill Huila Sand Diamond

Huila Sand Diamond Na Pahi Planer

Na Pahi Planer