What is the problem with edge banding?

Edgebanding refers to both the process and the strip of material used for creating aesthetically pleasing trim around unfinished edges of plywood, particle board, or MDF. Edgebanding increases the durability of a variety of projects like cabinetry and countertops, giving them a high-end, quality appearance.

Edgebanding requires versatility in terms of adhesive application. The temperature of the room, as well as the substrate, affects adhesion. Since edgebanding is made from many different materials, it is important to select an adhesive that offers the versatility and capability of being able to bond to a variety of substrates.

Hot melt glue is a multi-purpose adhesive used in a wide range of applications and suitable for pretty much all edge banding including PVC, melamine, ABS, acrylic and wood veneer. Hot melt is a great choice because it is affordable, it can be repeatedly re-melted, and is easy to work with.One of the disadvantages of hot melt adhesive edge sealing is that there are glue seams.

However, if the glue seams are obvious, it may be that the equipment has not been debugged properly. There are three main parts: pre-milling cutter part, rubber roller unit and pressure roller unit.

1. Abnormality in the pre-milling cutter part

-

If the base surface of the pre-milled board has ridges and the glue is unevenly applied, defects such as excessive glue lines will occur.The way to check whether the pre-milling cutter is normal is to turn off all units and only turn on the pre-milling cutter. After pre-milling MDF, observe whether the surface of the board is flat. -

If the pre-milled plate is uneven, the solution is to replace it with a new pre-milling cutter.

2. The rubber roller unit is abnormal.

-

There may be an error in the perpendicularity between the rubber coating roller and the base surface of the plate. You can use a square ruler to measure the perpendicularity. -

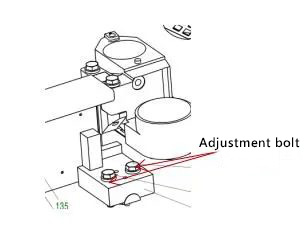

If the error is larger than 0.05mm, it is recommended to replace all milling cutters.When the glue coating pool is under industrial heat, the temperature is as high as 180°C and cannot be touched with bare hands. The simplest way to check is to find a piece of MDF, adjust the amount of glue to the minimum, and see if the glued end surface is even up and down. Make slight adjustments by adjusting the bolts so that the entire end face can be evenly applied with the smallest amount of glue.

3. The pressure wheel unit is abnormal

-

There are residual glue marks on the surface of the pressure wheel, and the surface is uneven, which will cause poor pressing effect. It needs to be cleaned up in time, and then check whether the air pressure and pressure wheel are normal. -

Errors in the verticality of the press wheel will also lead to poor edge sealing. However, you must first confirm that the base surface of the board is flat before adjusting the verticality of the press wheel.

Other commonest factors that affect the quality of edge banding

1,Equipment Problem

Because the engine of the edge banding machine and the track cannot cooperate well, the track is unstable during operation, then the edge banding strips will not fit the edge perfectly. the lack of glue or uneven coating are often caused by gluing pressure rod that does not cooperate well with the conveyor chain pad. If the trimming tools and the chamfering tools are not adjusted properly, not only requiring extra labor working, and the quality of trimming is difficult to guarantee.

In short, due to the poor level of equipment commissioning, repairs and maintenance, quality problems will last. The blunt of the cutting tools also directly affects the quality of the ends and trimming. The trimming angle given by the equipment is between 0 ~ 30 °, and the trimming angle selected in general production is 20 °. The blunt blade of the cutting tool will cause the surface quality to decrease.

2, The Workpiece

The man-made wooden as the material of workpiece, the thickness deviation and the flatness may not reach the standards. This makes the distance from the pressure roller wheels to the surface of the conveyor difficult to set. If the distance is too small, it will cause too much pressure and separate of the strips and workpiece. If the distance is too large, the plate will not be compressed, and the strips cannot be banded firmly with the edge.

3, Edge Banding Strips

The edge banding strips are mostly made of PVC, which can be greatly affected by the environment. In winter, the hardness of PVC strips will increase which causes the adhesion for the glue decreases. And the longer storage time, surface will age; the adhesive strength to the glue is lower. For paper made strips with a small thickness, due to their high toughness and low thickness (such as 0.3mm), will cause the uneven cuts, insufficient bonding strength, and poor trimming performance. So problems such as large waste of edge banding strips and high rework rate are serious.

4,Room Temperature and Machine Temperature

When the indoor temperature is low, the workpiece passes through the edge banding machine, its temperature cannot be increased quickly, and at the same time, the adhesive is cooled too quickly which is hard to complete the bonding. Therefore, the indoor temperature should be controlled above 15 ° C. If necessary, the parts of edge banding machine can be preheated before working (an electric heater can be added at the beginning of edge banding process). At the same time, the heating display temperature of the gluing pressure rod must be equal to or higher than the temperature which the hot melt adhesive can melt completely.

5,Feeding speed

The feeding speed of modern automatic edge banding machines is generally 18 ~ 32m / min. Some high-speed machines can reach 40m / min or higher, while the manual curve edge banding machine has a feeding speed of only 4 ~ 9m / min. The feeding speed of the automatic edge banding machine can be adjusted according to the edge banding strength. If the feeding speed is too high, although the production efficiency is high, the edge banding strength is low.

It’s our responsibility to edge band correctly. But you should know, there are still choices you’ll need to make when evaluating edge banding options.

Why choose HERO pre-milling cutter?

-

It can process various materials. The main processing materials are density board, particle board, multilayer plywood, fiberboard, etc. -

The blade is made of imported diamond material, and there is a perfect appearance of the tooth design quite with. -

Independent and beautiful package with carton and sponge inside, which can protection during transportation. -

It effectively solves the defects of non-durable and serious wear of carbide cutter. It can greatly improve the quality of product appearance. Give a long use life. -

No blackening, no edge fragmentation, perfect appearance of tooth design, completely in line with the processing technology. -

We have more than 20 years of experience and provide complete pre-sales and after-sales services. -

Excellent cutting quality in wood-based materials containing fibers.

Post time: Mar-01-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives