Bothata ke eng ka banding ba edge?

Edgebanding e bolela ts'ebetso le lesela la thepa le sebelisetsoang ho etsa trim e khahlehang ho pota-pota mapheo a sa phethoang a plywood, particle board kapa MDF. Edgebanding e eketsa nako e telele ea merero e fapaneng joalo ka likhabinete le li-countertops, e leng se fanang ka ponahalo ea boleng bo holimo.

Edgebanding e hloka ho feto-fetoha ha maemo mabapi le ts'ebeliso ea sekhomaretsi. Mocheso oa kamore, hammoho le substrate, o ama ho khomarela. Kaha edgebanding e entsoe ka lisebelisoa tse ngata tse fapaneng, ke habohlokoa ho khetha sekhomaretsi se fanang ka mefuta-futa le bokhoni ba ho khona ho tlamahane le mefuta e sa tšoaneng ea substrates.

Hot Melt glue ke sekhomaretsi sa mesebetsi e mengata se sebelisoang mefuteng e mengata ea lits'ebetso 'me se loketse bakeng sa band e ntle haholo e kenyelletsang PVC, melamine, ABS, acrylic le veneer ea lehong. Ho qhibiliha ho chesang ke khetho e ntle haholo hobane e theko e tlaase, e ka boela ea qhibiliha khafetsa, 'me e bonolo ho sebetsa le eona.E 'ngoe ea mathata a hot mellt adhesive Edge sealing ke hore ho na le li-seams tsa sekhomaretsi.

Leha ho le joalo, haeba li-seams tsa sekhomaretsi li hlakile, e ka 'na eaba thepa ha ea senyeha hantle. Ho na le likarolo tse tharo tse kholo: karolo ea pre-milling cutter, unit ea rabara ea rabara le yuniti ea rolara ea khatello.

1. Ho se tloaelehe karolong ea sehaho sa pele ho siloa

-

Haeba botlaaseng ba boto e entsoeng pele ho e-na le marapo 'me sekhomaretsi se sebelisoa ka tsela e sa tšoaneng, ho tla ba le mefokolo e kang mela ea sekhomaretsi se feteletseng. Ka mor'a MDF pele ho siloa, hlokomela hore na bokaholimo ba boto e bataletse. -

Haeba poleiti ea pre-milled e sa lekane, tharollo ke ho e nkela sebaka ka sehahi se secha sa pre-milling.

2. Sehlopha sa rabara sa rabara se sa tloaeleha.

-

Ho ka 'na ha e-ba le phoso ho perpendicularity pakeng tsa rolara ea ho roala rabara le bokaholimo ba poleiti. U ka sebelisa sekwere rula ho lekanya perpendicularity. -

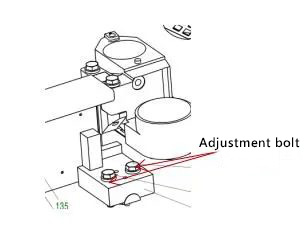

Haeba phoso e le kholo ho feta 0.05mm, ho kgothaletswa ho nkela li-cutters tsohle tsa milling sebaka. Tsela e bonolo ka ho fetisisa ea ho hlahloba ke ho fumana sengoathoana sa MDF, fetola palo ea sekhomaretsi hore e be bonyane, 'me u bone hore na karolo ea ho qetela e khomaretsoeng e le holimo le tlaase. Etsa liphetoho tse fokolang ka ho lokisa liboutu e le hore sefahleho sohle sa ho qetela se ka sebelisoa ka mokhoa o ts'oanang le sekhomaretsi se senyenyane ka ho fetisisa.

3. Karolo ea lebili la khatello ha e tloaelehe

-

Ho na le matšoao a setseng a sekhomaretsi holim'a lebili la khatello, 'me bokaholimo ha bo lekane, e leng se tla baka phello e mpe ea khatello. E hloka ho hloekisoa ka nako, ebe u hlahloba hore na khatello ea moea le lebili la khatello li tloaelehile. -

Liphoso tse holim'a verticality ea lebili la khatiso le tsona li tla lebisa tlhokomelong e fokolang ea ho tiisa. Leha ho le joalo, u tlameha ho qala ka ho netefatsa hore botlaaseng ba boto bo bataletse pele u lokisa ho theosa ha lebili la khatiso.

Lintlha tse ling tse tloaelehileng tse amang boleng ba li-edge banding

1, Bothata ba Lisebelisoa

Hobane enjene ea mochini oa banding ea bohale le pina ha e khone ho sebelisana hantle, pina ha e tsitsa nakong ea ts'ebetso, joale lithapo tsa banding li ke ke tsa lumellana hantle le moeli. ho haella ha sekhomaretsi kapa ho roala ho sa tšoaneng hangata ho bakoa ke molamu oa khatello ea gluing o sa sebelisane hantle le letlapa la ketane ea conveyor. Haeba lisebelisoa tsa ho kuta le lisebelisoa tsa chamfering li sa lokisoe hantle, ha li hloke mosebetsi o eketsehileng feela, 'me ho thata ho tiisa boleng ba ho kuta.

Ka bokhutšoanyane, ka lebaka la boemo bo bobe ba ho laela lisebelisoa, ho lokisoa le ho hlokomeloa, mathata a boleng a tla tšoarella. Bohlasoa ba lisebelisoa tsa ho itšeha bo boetse bo ama ka ho toba boleng ba lipheletsong le ho fokotsa. The angle trimming e fanoeng ke thepa e pakeng tsa 0 ~ 30 °, 'me trimming angle khethiloeng ka kakaretso tlhahiso ke 20 °. Lehare le hlabang la sesebelisoa sa ho itšeha le tla etsa hore boleng ba bokaholimo bo fokotsehe.

2, Mosebetsi

Lehong le entsoeng ke motho e le thepa ea mosebetsi, ho kheloha ha botenya le ho batalla ho ka 'na ha se ke ha fihla litekanyetso. Sena se etsa hore ho be thata ho beha sebaka sa mabili a rolara khatello ho ea holim'a conveyor. Haeba sebaka se le senyenyane haholo, se tla baka khatello e ngata haholo 'me se arohane le lihlopha le workpiece. Haeba sebaka se le seholo haholo, poleiti e ke ke ea hatelloa, 'me lihlopha li ke ke tsa tlamisoa ka thata ka bohale.

3, Melapo ea Banding ea Edge

Lithapo tse nang le lithapo li entsoe haholo ka PVC, e ka angoang haholo ke tikoloho. Mariha, ho thatafala ha lihlopha tsa PVC ho tla eketseha e leng se etsang hore ho khomarela sekhomaretsi ho fokotsehe. 'Me nako e telele ea polokelo, bokaholimo bo tla tsofala; matla a ho khomarela sekhomaretsi a tlaase. Bakeng sa likhoele tse entsoeng ka pampiri tse nang le botenya bo bonyenyane, ka lebaka la boima ba tsona bo phahameng le botenya bo tlase (joalo ka 0.3mm), li tla baka maqeba a sa lekaneng, matla a sa lekaneng a tlamahano, le ts'ebetso e mpe ea ho kuta. Kahoo mathata a kang litšila tse kholo tsa li-edge banding strips le sekhahla se phahameng sa rework a tebile.

4, Mocheso oa Kamore le Mocheso oa Mochini

Ha mocheso o ka hare o le tlase, mochine oa mosebetsi o feta mochine oa ho kopanya ka bohale, mocheso oa oona o ke ke oa eketseha ka potlako, 'me ka nako e ts'oanang, sekhomaretsi se pholile ka potlako se thata ho qeta ho kopanya. Ka hona, mocheso o ka hare o lokela ho laoloa ka holimo ho 15 ° C. Haeba ho hlokahala, likarolo tsa mochine oa banding o bohale o ka futhumatsoa pele o sebetsa (mocheso oa motlakase o ka eketsoa qalong ea mokhoa oa ho kopanya ka bohale). Ka nako e ts'oanang, mocheso oa pontšo ea mocheso oa molamu oa khatello ea gluing o tlameha ho lekana kapa o phahame ho feta mocheso oo sekhomaretsi se chesang se chesang se ka qhibilihang ka ho feletseng.

5,Ho fepa lebelo

Lebelo la ho fepa la mechini ea sejoale-joale e ikopantseng ea othomathike hangata ke 18 ~ 32m / min. Mechini e meng e lebelo le holimo e ka fihla ho 40m / min kapa ho feta, ha mochini oa li-curve curve o na le lebelo la ho fepa la 4 ~ 9m / min feela. Lebelo la ho fepa la mochini o kopanyang o ikemetseng o ka fetoloa ho ea ka matla a banding. Haeba lebelo la ho fepa le phahame haholo, le hoja katleho ea tlhahiso e phahame, matla a ho kopanya ka bohale a tlaase.

Ke boikarabello ba rona ho hlophisa sehlopha ka nepo. Empa u lokela ho tseba, ho ntse ho na le likhetho tseo u tla hloka ho li etsa ha u lekola likhetho tsa banding.

Hobaneng u khetha HERO pre-milling cutter?

-

E ka sebetsana le lisebelisoa tse fapaneng. Lisebelisoa tse ka sehloohong tsa ts'ebetso ke boto ea boima, boto ea likaroloana, plywood ea multilayer, fiberboard, joalo-joalo. -

Lehare le entsoe ka thepa ea daemane e tsoang kantle ho naha, 'me ho na le ponahalo e phethahetseng ea moralo oa leino hantle. -

Sephutheloana se ikemetseng le se setle se nang le lebokose le seponche ka hare, se ka sireletsang nakong ea lipalangoang. -

E rarolla ka katleho mefokolo ea moaparo o sa tšoarelleng le o tebileng oa seha se seha sa carbide. E ka ntlafatsa haholo boleng ba ponahalo ea sehlahisoa. Fana ka bophelo bo bolelele ba tšebeliso. -

Ha ho na blackening, ha ho na karohano ea bohale, ponahalo e phethahetseng ea moralo oa leino, e lumellanang ka ho feletseng le theknoloji ea ho sebetsa. -

Re na le boiphihlelo ba lilemo tse fetang 20 mme re fana ka lits'ebeletso tse felletseng tsa pele ho thekiso le kamora ho rekisa. -

Boleng bo babatsehang ba ho itšeha ka thepa e entsoeng ka lehong e nang le likhoele.

Nako ea poso: Mar-01-2024

TCT Saw Blade

TCT Saw Blade MOHALE Sizing Saw Blade

MOHALE Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw MOHALE Ho Koanya Saw Blade

MOHALE Ho Koanya Saw Blade MOHALE Sefate se Tiileng Saw Blade

MOHALE Sefate se Tiileng Saw Blade MOHALE Aluminium Saw

MOHALE Aluminium Saw Grooving Saw

Grooving Saw Boemo ba tšepe bo bone

Boemo ba tšepe bo bone Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminium Saw

PCD Aluminium Saw Cold Saw bakeng sa Tšepe

Cold Saw bakeng sa Tšepe Cold Saw Blade ea Ferrous Metal

Cold Saw Blade ea Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Li-Dowel Drill Bits

Li-Dowel Drill Bits Ka li-Drill Bits

Ka li-Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Lisebelisoa tsa router

Lisebelisoa tsa router Likotoana tse otlolohileng

Likotoana tse otlolohileng Likotoana tse telele tse otlolohileng

Likotoana tse telele tse otlolohileng Li-bits tse otlolohileng tsa TCT

Li-bits tse otlolohileng tsa TCT Li-Bits tsa M16 tse otlolohileng

Li-Bits tsa M16 tse otlolohileng TCT X Likotoana tse otlolohileng

TCT X Likotoana tse otlolohileng 45 Degree Chamfer Bit

45 Degree Chamfer Bit Ho betla Bit

Ho betla Bit Corner Round Bit

Corner Round Bit Lisebelisoa tsa router tsa PCD

Lisebelisoa tsa router tsa PCD Lisebelisoa tsa Edge Banding

Lisebelisoa tsa Edge Banding TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Lisebelisoa le Lisebelisoa tse ling

Lisebelisoa le Lisebelisoa tse ling Li-adapter tsa ho cheka

Li-adapter tsa ho cheka Drill Chucks

Drill Chucks Lebili la Lehlabathe la Diamond

Lebili la Lehlabathe la Diamond Lithipa tsa Planer

Lithipa tsa Planer