Iyiphi i-saw blade engcono kakhulu yokusika i-aluminium?

Imishini yokusika i-Aluminium iyithuluzi elibalulekile lokusika, ikakhulukazi embonini yokucubungula amafasitela kanye nomnyango.Kunezinhlobo eziningi ezihlukene, ezihlanganisa ngokugcwele okuzenzakalelayo kanye ne-semi-automatic.Zingabuye zihlukaniswe zibe izinhlobo zetafula kanye nezinhlobo eziphathwa ngesandla ngokusho kobukhulu bazo.

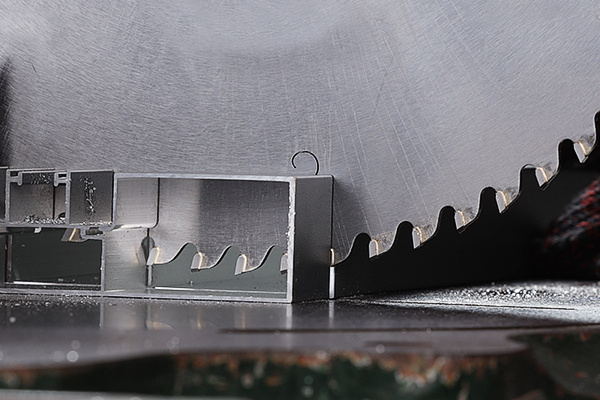

Enqubweni yokucutshungulwa kwe-aluminium iminyango namafasitela umshini wokusika amafasitela nomnyango kubaluleke kakhulu, ngakho-ke ungakhetha kanjani i-saw blade efanele yomshini wokusika we-aluminium wokusika okungcono?

Kunezinhlobo eziningi zama-saha izindwani ezitholakala emakethe ezihambisana nemishini yokusika i-aluminium, futhi into yokuqala okufanele siyicabangele lapho sikhetha i-saw blade yizinto ezibonakalayo.

Izinto ezihlukene ze-saha blade ekusetshenzisweni ukudlala indima azifani neze, ekucubunguleni iminyango namafasitela ngokuvamile sisebenzisa ingxube ye-aluminium eqinile njengezinto eziyisisekelo, noma sisebenzisa amandla ensimbi evelele kakhulu yepulasitiki njengento eyinhloko, ngamafuphi, ukukhethwa kwezinto kuyisiqinisekiso somphumela wokusika womshini wokusika we-aluminium.

Ngaphezu kwezinto ezibonakalayo, umshini wokusika i-aluminium ungakhetha kanjani i-saw blade? - I-diameter ye-saw blade

Ububanzi be-saw blade nakho kungenye yezinto ezingenakunakwa, okuqondakala kakhulu, iphrofayili yokuqina efanayo, ukujula kokusika kuhlukile ngamadayimitha ahlukene we-saw blade, ukukhethwa kobubanzi be-saw blade nakho kungenye yemininingwane u-opharetha adinga ukuyinaka, isidingo sokuqoqa izakhiwo ezihlukahlukene zezinto zokusika ukuze zicutshungulwe.

Ukufingqa, ungakhetha kanjani i-saw blade efanelekile yomshini wokusika we-Aluminium?

Kunezici eziningi okufanele zicatshangelwe, kufaka phakathi ububanzi be-saw blade, inani lamazinyo, izinto ezibonakalayo kanye nezinye izici ezibalulekile ezithinta ukusebenza kokusika.

Inombolo yamazinyo we-saw blade ibaluleke kakhulu.Ukusebenza kokusika komshini wokusika i-aluminium ngokuvamile ukukhuluma ngamazinyo okusika. Lapho amazinyo engeziwe, umkhawulo wokusika kakhulu iyunithi ngayinye yesikhathi, ukusebenza okuhambisanayo kokusika umshini kuzoba okuvelele kakhulu. Kodwa into eyodwa kufanele kuqashelwe ukuthi inani amazinyo on the isaha blade ngokuvamile yakhiwa carbide ehambisana esetshenziswa futhi ngaphezulu, okuzokwenza aluminium cutting umshini ukuba athambekele kakhudlwana ukushisa in inqubo ukusika.

Uma kukhona amazinyo amaningi, kulapho esondelana khona, okuzokwenza ukuguga nokuklebhuka kukhuphuke kakhulu. Umshini wokusika i-aluminium jikelele ngokuvamile udinga ukulawulwa phakathi kuka-15-25mm, okubuye kube umthetho wegolide we-tooth pitch yemishini yokusika i-aluminium. Ngamafuphi, inani lamazinyo liyisici se-saw blade ngokwayo, kodwa futhi isici esibalulekile esithinta ukusebenza kokusika komshini wokusika i-aluminium.

1. Ukucaciswa kwemodeli yomshini wokusika i-aluminium kanye nobubanzi be-saw blade

Ngokuvamile, umshini wokusika we-aluminium we-455 ufakwe i-aluminium cutting saw blade enobubanzi obungu-455mm noma 405mm. Uma sikhuluma ngokwethiyori, ngeke ifakwe i-aluminium cutting saw blade enobubanzi obungaphezu kuka-455mm, kodwa abasebenzisi abazi ukuthi kanjani. Ifakwe i-aluminium cutting saw blade ububanzi bayo buncane kakhulu ukunciphisa umthamo wokusika umshini wokusika we-aluminium.

Kufanele futhi kukhunjulwe ukuthi ububanzi be-shaft eyinhloko yemishini yokusika i-aluminium ithinta ububanzi bangaphakathi be-aluminium cutting saw blade. Kodwa-ke, ububanzi be-shaft eyinhloko yemishini yokusika i-aluminium yabasebenzisi abaningi akuyona i-25.4mm noma i-30mm evamile, futhi ububanzi obuguquguqukayo buyadingeka. isethi noma imbobo yokukhulisa, kanye namasaha e-aluminium cutting athengiswa emakethe amadayamitha angaphakathi avamile. Kunconywa ukuya kumkhiqizi ukuze ubuze, okungaxazulula kalula inkinga yomsebenzisi yokwandisa imbobo kanye nama-saw blades angewona ama-aluminiyamu enziwe ngezifiso!

2. Ukunemba kwe-spindle yomshini wokusika i-aluminium kuthinta impilo yesevisi ye-saw blade.

Uma sikhuluma ngokwethiyori, ukuphakama kokunemba kwe-spindle yomshini wokusika i-aluminium, kungcono, ngoba ukuphakama kokunemba kwe-spindle, kuba kuncane ukuchezuka kwensingo yesaha ye-aluminium, kuba ngcono umphumela wangempela wokusika, futhi kuba ngcono impilo yesevisi ye-alloy saw blade. Ngakolunye uhlangothi, abasebenzisi abaningi abasika ama-workpieces omkhiqizo wephrofayili ye-aluminium alloy amancane bafuna ukusebenzisa ama-saha ama-ultra-mncane amancane ukuze bonge izindleko, futhi banezidingo zokunemba eziphakeme kakhulu zemishini yokuphotha yomshini wokusika we-aluminium, ngokuvamile ngaphakathi kocingo olulodwa.

Kodwa-ke, ukunemba kwe-axis eyinhloko yomshini wokusika i-aluminium wabakhiqizi abaqeqeshiwe kulawulwa ngokuzinzile ngaphakathi kwe-0.01mm. Ngisho noma umsebenzisi engasebenzisi i-ultra-thin alloy saw blade, idlala indima ekuvikeleni impilo yesevisi ye-aluminium cutting saw blade. Ery ambalwa aluminium cutting saw blades ezindaweni ezifana Shandong/Zhangjiagang/Guangdong angafinyelela ukunemba ngaphakathi kwentambo eyodwa yokuphotha imishini.

3. Isivinini se-motor yomshini wokusika i-aluminium sithinta ukukhethwa kwezinto ezibonakalayo ze-saw blade

Isivinini sokujikeleza somshini wokusika i-aluminium ngokuvamile sizungeze i-2800r/min. Isivinini sokujikeleza somshini wokusika i-aluminium singabuye sifinyelele cishe ku-5000 kuya ku-6000r / min, okungaqinisekisa kangcono ukunemba kwe-flatness nokushelela kwendawo yokusika. Kodwa-ke, ama-saha ama-aluminium enziwe ngezinto ezithile awakwazi ukubekezelela isivinini esikhulu. Impahla ye-aluminium cutting saw blades esetshenziswa abakhiqizi abangochwepheshe uchungechunge lwe-SKS olungeniswe lusuka eJapan. Ifaneleka kakhulu ukusetshenziswa emishinini yokusika i-aluminium. Ingakwazi ukuqedela ukusika izinhlobo ezihlukahlukene zamaphrofayili e-aluminium alloy, amapuleti e-aluminium alloy, izinduku ze-aluminium, i-aluminium alloy die castings, nezifanekiso ze-aluminium. , i-aluminium motor casing namanye amaphrofayili e-aluminium alloy.

Gcoba I-Circular Saw Blade Ukuze Uvikeleke Okungeziwe

Ingozi enkulu kakhulu yokusika i-aluminium ngesaha esiyindilinga yi-blade ebamba impahla. Sebenzisa ukuthambisa ukuze ugcine i-blade ingagxili nemfucumfucu noma ibambe into. I-lubrication iphinde ivikele i-blade futhi ivimbele ukushisa ngokweqile, ukunciphisa ingozi yamathiphu aqoshiwe.

Hlala Ucindezela Izinto Ngokufanele

Ngemuva kokukhetha i-blade efanele kanye nokugcoba, udinga ukuvikela i-aluminium. Isaha ibambezela phansi impahla njengoba usika kuyilapho isaha eliyindilinga likwazi ukudonsa. Ukuze ugcine okokusebenza kuvikelekile, sebenzisa ama-clamp amaningi.

Isiphetho

Ukusika i-aluminium ngesaha esiyindilinga kudinga izinyathelo ezikhethekile ezimbalwa. Qinisekisa ukuthi une-blade efanele. I-blade evamile ingase ibambe impahla. Uma kungenzeka, thenga i-blade eklanyelwe ngokukhethekile ukusika i-aluminium nezinye izinto ezingezona ayoni.

Ukukhetha umkhiqizi we-saha we-aluminium wokusika ofanele nakho kubalulekile, i-HERO ingumkhiqizi we-aluminium cutting saw blade, wamukelekile amakhasimende anentshisekelo ukuthi asikhethe.

Isikhathi sokuthumela: Mar-08-2024

I-TCT Saw Blade

I-TCT Saw Blade IQHAWE Sizing Saw Blade

IQHAWE Sizing Saw Blade I-HERO Panel Sizing Saw

I-HERO Panel Sizing Saw IQHAWE Lokushaya I-Saw Blade

IQHAWE Lokushaya I-Saw Blade IQHAWE Eliqinile Izinkuni Saw Blade

IQHAWE Eliqinile Izinkuni Saw Blade IQHAWE Aluminium Saw

IQHAWE Aluminium Saw I-Grooving Saw

I-Grooving Saw Iphrofayili Yensimbi Yabona

Iphrofayili Yensimbi Yabona I-Edge Bander Saw

I-Edge Bander Saw I-Acrylic Saw

I-Acrylic Saw I-PCD Saw Blade

I-PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade I-PCD Panel Sizing Saw

I-PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade I-PCD Grooving Saw

I-PCD Grooving Saw I-PCD Aluminium Saw

I-PCD Aluminium Saw I-Cold Saw Yensimbi

I-Cold Saw Yensimbi Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal I-Dry Cut Saw Blade ye-Ferrous Metal

I-Dry Cut Saw Blade ye-Ferrous Metal Cold Saw Machine

Cold Saw Machine I-Drill Bits

I-Drill Bits Izingcezu ze-Dowel Drill

Izingcezu ze-Dowel Drill Nge-Drill Bits

Nge-Drill Bits Ama-Hinge Drill Bits

Ama-Hinge Drill Bits TCT Isinyathelo Drill Bits

TCT Isinyathelo Drill Bits HSS Drill Bits/Mortise Bits

HSS Drill Bits/Mortise Bits Ama-router Bits

Ama-router Bits Amabhithi Aqondile

Amabhithi Aqondile Izingcezu Ezinde Eziqondile

Izingcezu Ezinde Eziqondile Amabhithi Aqondile we-TCT

Amabhithi Aqondile we-TCT I-M16 Amabhithi Aqondile

I-M16 Amabhithi Aqondile I-TCT X Amabhithi Aqondile

I-TCT X Amabhithi Aqondile 45 Degree Chamfer Bit

45 Degree Chamfer Bit I-Carving Bit

I-Carving Bit I-Corner Round Bit

I-Corner Round Bit I-PCD Router Bits

I-PCD Router Bits Edge Banding Amathuluzi

Edge Banding Amathuluzi I-TCT Fine Trimming Cutter

I-TCT Fine Trimming Cutter I-TCT Pre Milling Cutter

I-TCT Pre Milling Cutter I-Edge Bander Saw

I-Edge Bander Saw I-PCD Fine Trimming Cutter

I-PCD Fine Trimming Cutter I-PCD Pre Milling Cutter

I-PCD Pre Milling Cutter I-PCD Edge Bander Saw

I-PCD Edge Bander Saw Amanye Amathuluzi Nezesekeli

Amanye Amathuluzi Nezesekeli I-Drill Adapter

I-Drill Adapter Drill Chucks

Drill Chucks Isondo Lesanti Ledayimane

Isondo Lesanti Ledayimane Imimese Yokuhlela

Imimese Yokuhlela