What saw blade is best for cutting aluminum?

Aluminium Cutting Machines are an important cutting tool, especially in the window and door processing industry.There are many different types, including fully automatic and semi-automatic.They can also be divided into table-top and hand-held types according to their size.

In the process of window and door processing aluminium doors and windows cutting machine is extremely important, so how to choose the right saw blade of the aluminum cutting machine for better cutting?

There are many types of saw blades available on the market that are compatible with aluminium cutting machines, and the first thing we should consider when choosing a saw blade is the material.

Different materials of the saw blade in the use to play a role are not quite the same, in the process of processing doors and windows we generally use rigid aluminum alloy as the basic material, or use the strength of more outstanding plastic steel as the main material, in short, the choice of material is a guarantee of the cutting effect of the aluminum cutting machine.

In addition to the material, aluminum cutting machine how to choose a saw blade? —The saw blade diameter

The diameter of the saw blade is also one of the factors that cannot be ignored, which is also very understandable, the same thickness profile, the cutting depth is different with different diameters of the saw blade, the choice of saw blade diameter is also one of the details that the operator needs to pay attention to, the need to collect the various properties of the cutting material for comprehensive consideration.

To sum up, how to choose a suitable saw blade for Aluminium Cutting Machine?

There are many factors to consider, including the diameter of the saw blade, the number of teeth, material and other important factors that affect the cutting performance.

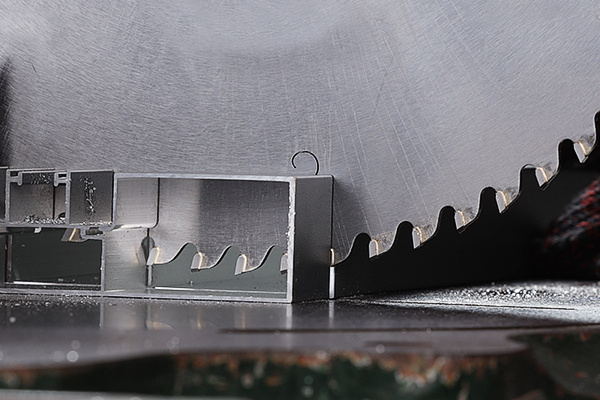

The number of teeth of the saw blade is very important.The cutting performance of the aluminium cutting machine generally speaking is the cutting teeth. The more teeth, the more cutting edge per unit of time, the corresponding machine cutting performance will be more outstanding. But one thing should be note is that the number of teeth on the saw blade is generally made up of the corresponding carbide that used is also more, which will cause the aluminum cutting machine to be more prone to heat in the process of cutting.

The more teeth there are, the closer they are to each other, which will make the overall wear and tear tremendously rise. The general aluminium cutting machine generally needs to be controlled between 15-25mm, which is also the golden rule of tooth pitch for aluminium cutting machines. In short, the number of teeth is a factor of the saw blade itself, but also an important factor that affects the cutting performance of the aluminum cutting machine.

1. Aluminum cutting machine model specifications and saw blade diameter

Generally speaking, the 455 aluminum cutting machine is equipped with an aluminum cutting saw blade with a diameter of 455mm or 405mm. Theoretically speaking, it cannot be equipped with an aluminum cutting saw blade with a diameter of more than 455mm, but users do not know how. Equipped with an aluminum cutting saw blade whose diameter is too small to reduce the cutting capacity of the aluminum cutting machine.

It should also be reminded that the main shaft diameter of the aluminum cutting machine equipment affects the inner diameter of the aluminum cutting saw blade. However, the main shaft diameter of the aluminum cutting machine equipment of many users is not the conventional 25.4mm or 30mm, and a variable diameter is required. set or hole enlarging, and the aluminum cutting saw blades sold on the market are conventional inner diameters. It is recommended to go to the manufacturer to inquire, which can easily solve the user’s hole enlarging problem and non-standard customized aluminum cutting saw blades!

2. The spindle accuracy of the aluminum cutting machine affects the service life of the saw blade.

Theoretically speaking, the higher the accuracy of the spindle of the aluminum cutting machine, the better, because the higher the accuracy of the spindle, the smaller the deflection of the aluminum saw blade, the better the actual cutting effect, and the better the service life of the alloy saw blade. On the other hand, many users who cut small aluminum alloy profile product workpieces want to use ultra-thin aluminum cutting saw blades to save costs, and have relatively high accuracy requirements for the equipment spindle of the aluminum cutting machine, usually within one wire.

However, the accuracy of the main axis of the aluminum cutting machine of professional manufacturers is stably controlled within 0.01mm. Even if the user does not use an ultra-thin alloy saw blade, it plays a role in protecting the service life of the aluminum cutting saw blade. ery few aluminum cutting saw blades in areas such as Shandong/Zhangjiagang/Guangdong can achieve an accuracy within one filament of the equipment spindle.

3. The motor speed of the aluminum cutting machine affects the selection of saw blade material

The rotation speed of the aluminum cutting machine is generally around 2800r/min. The rotation speed of the aluminum cutting machine can also reach around 5000 to 6000r/min, which can better ensure the flatness accuracy and smoothness of the cutting surface. However, aluminum cutting saw blades made of some materials cannot bear high speeds. The material of aluminum cutting saw blades used by professional manufacturers is the SKS series imported from Japan. It is very suitable for use on aluminum cutting machines. It can complete the cutting of various types of aluminum alloy profiles, aluminum alloy plates, aluminum rods, aluminum alloy die castings, and aluminum templates. , aluminum motor casing and other aluminum alloy profiles.

Lubricate The Circular Saw Blade For Added Protection

The biggest risk of cutting aluminium with a circular saw is the blade grabbing the material. Use lubrication to keep the blade from gumming up with debris or catching on the material. The lubrication also protects the blade and prevents overheating, reducing the risk of chipped tips.

Always Clamp The Materials Properly

After choosing the right blade and lubrication, you need to secure the aluminium. A miter saw clamps down the material as you cut while a circular saw can pull. To keep the material secure, use multiple clamps.

Conclusion

Cutting aluminium with a circular saw requires a few special steps. Ensure that you have the right blade. An ordinary blade is more likely to grab the material. If possible, purchase a blade specially designed for cutting aluminium and other non-ferrous materials.

Choosing the right aluminium cutting saw blade manufacturer is also indispensable, HERO is a professional aluminum cutting saw blade manufacturers, welcome interested customers to choose us

Post time: Mar-08-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives