intshayelelo

I-jointer ngumatshini wokwenza umthi osetyenziselwa ukuvelisa indawo ethe tyaba ecaleni kobude bebhodi.Sesona sixhobo siqhelekileyo sokucheba.

Kodwa ngokwenene i-jointer isebenza njani? Ziziphi iintlobo ezahlukeneyo zeejoyinti? Kwaye yintoni umehluko phakathi kwe-jointer kunye neplani?

Eli nqaku lijolise ekuchazeni iziseko zoomatshini bokudibanisa, kubandakanywa nenjongo yabo, indlela abasebenza ngayo, kunye nendlela yokuyisebenzisa ngokuchanekileyo.

Isiqulatho

-

Yintoni iJointer

-

Indlela Esebenza ngayo

-

Yintoni uMcwangcisi

-

Umahluko phakathi koMdibanisi kunye noMcwangcisi

Yintoni jointer

A umdibanisiyenza ubuso bebhodi ejijekileyo, ejijekileyo, okanye egobileyo. Emva kokuba iibhodi zakho zisicaba, i-jointer ingasetyenziselwa ukulungisa imida yesikwere

Njengeumdibanisi, umatshini usebenza kumda omncinci weebhodi, uzilungiselela ukuba zisetyenziswe njenge-butt joint okanye igluing kwiipaneli.

Isicwangciso sokudibanisa isicwangcisi sinobubanzi obuvumela ukugudiswa (ukucwangciswa komphezulu) kunye nokulinganisa ubuso (ububanzi) beebhodi ezincinci ngokwaneleyo ukuba zilungele iitafile.

Injongo:mcaba, mtyibilizi, kunye nesikwere .ilungisa iziphene zemathiriyeli

Uninzi lwemisebenzi yemithi inokwenziwa ngoomatshini okanye ngesandla. I-jointer yinguqulelo yomatshini yesixhobo sesandla esibizwa ngokuba yi-jointer plane.

Icandelo

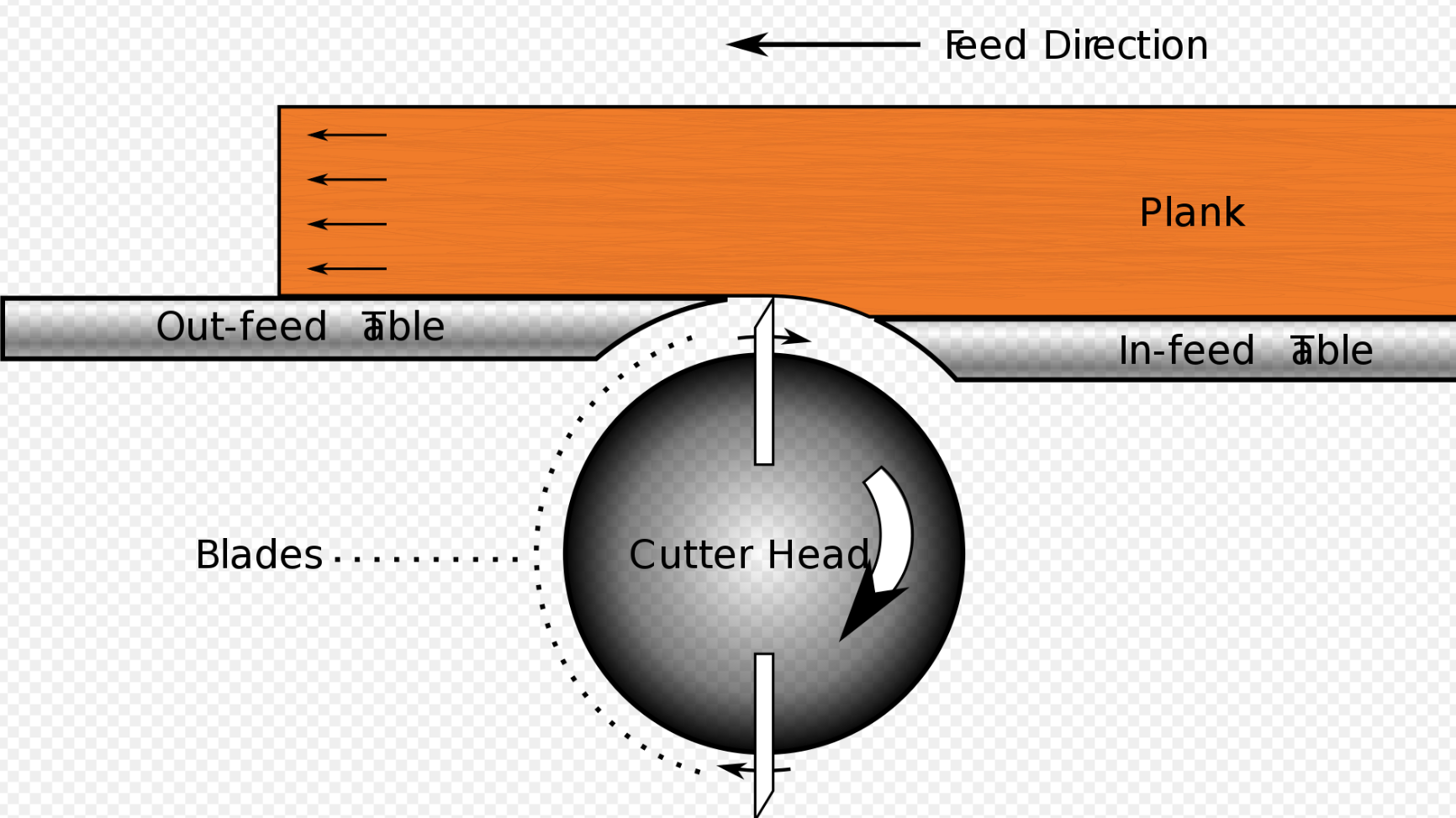

Ijoyinti inamalungu amane aphambili:itafile ye-infeed, itafile ye-outfeed, ucingo, kunye nentloko yokusika.La macandelo mane asebenza kunye ukwenza iibhodi zibe mcaba kunye ne-edges yesikweri.

Ijoyinti inamalungu amane aphambili:itafile ye-infeed, itafile ye-outfeed, ucingo, kunye nentloko yokusika.La macandelo mane asebenza kunye ukwenza iibhodi zibe mcaba kunye ne-edges yesikweri.

Ngokusisiseko, isicwangciso setafile yejoyintisi siyilwe ngamanqanaba amabini afana neplani yobukhulu obumxinwa ukuze iqulathe iitafile ezimbini ezinde, ezimxinwa ezinxuseneyo ezilandelelanayo kunye nentloko yomsiki ephakathi phakathi kwazo, kodwa inesikhokelo esisecaleni.

Ezi theyibhile zibizwa ngokuba yi-infeed kunye ne-outfeed.

Njengoko kubonisiwe kumzobo, Itafile ye-infeed ibekwe ngaphantsi kancinci kune-cutterhead.

Intloko yokusika iphakathi kwebhentshi yokusebenzela, kwaye umphezulu wentloko yayo yokusika ugungxulwe netafile ephumayo.

Iincakuba zokusika zilungelelanisiwe ukuze zihambelane nomphakamo kunye nepitch ye (& yenziwe isikwere ukuya) kwitafile ephumayo.

Ingcebiso ngokhuseleko: Itheyibhile ephumayo akufunekanga ibephezulu kune-cutterhead. Ngaphandle koko, iibhodi ziya kuyeka xa zifikelela kumda).

Iitafile ze-infeed kunye ne-outfeed zi-coplanar, oku kuthetha ukuba zikwinqwelomoya enye kwaye zithe tyaba ngokupheleleyo.

Ubungakanani obuqhelekileyo: Izidibanisi zeeworkshop zasekhaya zihlala zine-4-6 intshi (100-150mm) ububanzi bokusikwa. Oomatshini abakhulu, bahlala beyi-8-16 intshi (200-400mm), basetyenziswa kwiindawo zoshishino.

Indlela Esebenza ngayo

Umsebenzi oza kucwangciswa kwiflethi ubekwe kwitafile ye-infeed kwaye udluliselwe phezu kwentloko ye-cutter kwi-outfeed table, ngononophelo oluthathiweyo ukugcina isantya sokutya rhoqo kunye noxinzelelo oluphantsi.

Isiqwenga somsebenziukuba icwangciswe tyaba ibekwe phezu kwetafile infeed kwaye wadlula phezu kwentloko cutter kwitafile outfeed, ngenkathalo ethathiweyo ukugcina isantya feed rhoqo kunye noxinzelelo ezantsi.

Xa kuziwa kwimida ye-squaring, ucingo lwe-jointer lubamba iibhodi kwi-90 ° kwi-cutterhead ngelixa kwenziwa inkqubo efanayo.

Nangona iindawo ezidityanisiweyo zisetyenziselwa ukungqusha, zinokusetyenziselwa **ukusika ii-chamfers, iirabbets, kunye neetaper

Phawula:Izihlanganisi azenzi buso obuchasayo kunye nemiphetho ehambelanayo.

Olo luxanduva lomcwangcisi.

Ukusetyenziswa okukhuselekileyo

Njengawo nawuphi na umsebenzi wesixhobo somthi, landela izikhokelo ezimbalwa, kwaye ukhangele iinkcukacha ngaphambi kokusetyenziswa. Yeyona ndlela yokuqinisekisa ukhuseleko lwakho

Ngoko ke ndiza kukuxelela iingcebiso zokhuseleko

-

QINISEKISA ISIBAMBI SAKHO SISEKWE NGOKULUNGILEYO

Yenza iindawo ezine zejoyinti,itafile ye-infeed, itafile ye-outfeed, ucingo, kunye nentloko yokusika.Nganye ikumphakamo ochanekileyo, njengoko kukhankanyiwe ngasentla.

Kwakhona qiniseka ukusebenzisa iipaddles xa uthambisa iibhodi.

-

PHAWULA UBUSO IBHODI UKUTHI BHABEKE

Injongo

cacisa ukuba bubuphi ubuso bebhodi oza kucaba.

cacisa ukuba bubuphi ubuso bebhodi oza kucaba.Wakuba wenze isigqibo ebusweni, bhala kuyo yonke indawo ngepensile.

Imigca yeepensile iya kubonisa xa ubuso buthe tyaba. (ipensile imkile = flat). -

YONZA IBHODI NGOKU

Qala ngokubeka ibhodi ibe mcaba phezu kwetafile ye-infeed kwaye uyityhale kwi-cutterhead ngesandla ngasinye sibambe i-paddle yokutyhala.

Ngokuxhomekeke kubude bebhodi, unokufuneka uhambise izandla zakho ngasemva naphambili phezu komnye.

Nje ukuba ibhodi idlulile kwi-cutterhead yokubeka i-paddle yokutyhala, beka lonke uxinzelelo kwicala letafile ephumayo.

Qhubeka utyhala ibhodi de i-blade guard ivale kwaye igqume i-cutterhead.

Yintoni uMcwangcisi?

Isicwangcisi sokutyeba(ekwabizwa ngokuba yi-UK kunye ne-Australia njenge-thicknesser okanye eNyakatho Melika njengeplani) ngumatshini wokwenza umthi wokusika iibhodi ukuya kubukhulu obuhambelanayo kubo bonke ubude bawo.

Isicwangcisi sokutyeba(ekwabizwa ngokuba yi-UK kunye ne-Australia njenge-thicknesser okanye eNyakatho Melika njengeplani) ngumatshini wokwenza umthi wokusika iibhodi ukuya kubukhulu obuhambelanayo kubo bonke ubude bawo.

Lo matshini ubhala ubukhulu obufunwayo usebenzisa icala elisezantsi njengesalathiso / isalathisi. Ngoko, ukuvelisaibhodi ecwangcisiweyo ngokupheleleyokufuna ukuba umphezulu ophantsi uthe tye phambi kokucwangciswa.

Umsebenzi:

Iplani ye-thickness planer ngumatshini wokwenza umthi wokusika iibhodi ukuya kubukhulu obuhambelanayo kubo bonke ubude bazo kunye nesicaba kuzo zombini iindawo.

Nangona kunjalo i-thickness ineenzuzo ezibaluleke ngakumbi kuba inokuvelisa ibhodi enobunzima obuhambelanayo.

Ukuphepha ukuvelisa ibhodi ene-tapered, kwaye ngokwenza amapasi kwicala ngalinye kunye nokujika ibhodi, ingasetyenziselwa ukulungiswa kokuqala kwebhodi engacwangciswanga.

Amacandelo:

Isicwangcisi esityebileyo siquka izinto ezintathu:

-

intloko yokusika (equlethe iimela zokusika); -

isethi ye-roller (ezoba ibhodi ngomatshini); -

itafile (ehlengahlengiswayo xa ithelekiswa nentloko yomsiki ukulawula ubunzima bebhodi.)

Indlela Yokusebenza

-

itheyibhile ibekwe kumphakamo ofunekayo kwaye emva koko umatshini uvulwa. -

Ibhodi yondliwa kumatshini ide idibane ne-roller ye-feed: -

Iimela zisusa izinto endleleni kwaye i-out-feed roller idonsa ibhodi kwaye iyikhuphe kumatshini ekupheleni kokudlula.

Umahluko phakathi koMdibanisi kunye noMcwangcisi

-

Isicwangcisi Yenza izinto zihambelane ngokupheleleyo okanye zibe nobukhulu obufanayo

-

Isihlanganisi bubuso okanye silungelelanise kwaye sisikweri emphethweni,Yenza izinto zibe flat

NgokweMiqathango yeMpembelelo yokuLungiselela

Zinomsebenzi owahlukileyo wokujonga umphezulu.

-

Ke ukuba ufuna into enobungqingqwa obufanayo kodwa ingabi mcaba, unokusiqhuba isicwangcisi.

-

Ukuba ufuna imathiriyeli enamacala amabini asicaba kodwa ubukhulu obahlukeneyo, qhubeka usebenzisa ijoyini.

-

Ukuba ufuna ibhodi etyebileyo kunye necaba ngokulinganayo, faka izinto kwi-jointer kwaye usebenzise iplani.

Nceda qaphela

Qinisekisa ukusebenzisa i-jointer ngononophelo kwaye ulandele iinkcukacha ezikhankanywe ngaphambili ukuze uhlale ukhuselekile.

Thina izixhobo koocut.

Ukuba unomdla, sinokukunika izixhobo ezingcono.

Pls khululeka uqhagamshelane nathi.

Ixesha lokuposa: Jan-18-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Ubungakanani Saw

HERO Panel Ubungakanani Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade IQHAWE LOKUQHUBEKA kweenkuni zabona iBlade

IQHAWE LOKUQHUBEKA kweenkuni zabona iBlade HERO Aluminiyam Saw

HERO Aluminiyam Saw I-Grooving Saw

I-Grooving Saw Iprofayile yentsimbi yabona

Iprofayile yentsimbi yabona Edge Bander wabona

Edge Bander wabona Saw Acrylic

Saw Acrylic PCD Saw Blade

PCD Saw Blade PCD Ubungakanani beSaw Blade

PCD Ubungakanani beSaw Blade PCD Panel Ubungakanani Saw

PCD Panel Ubungakanani Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminium Saw

PCD Aluminium Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Metal Ferrous

Cold Saw Blade for Metal Ferrous Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Umtshini weSaw obandayo

Umtshini weSaw obandayo Drill Bits

Drill Bits Amasuntswana eDowel Drill

Amasuntswana eDowel Drill Ngokusebenzisa i-Drill Bits

Ngokusebenzisa i-Drill Bits Amasuntswana e-Hinge Drill

Amasuntswana e-Hinge Drill TCT Inyathelo Drill Bits

TCT Inyathelo Drill Bits HSS Drill Bits / Mortise Bits

HSS Drill Bits / Mortise Bits Amasuntswana eRouter

Amasuntswana eRouter Amasuntswana aNgqo

Amasuntswana aNgqo Amasuntswana amade athe ngqo

Amasuntswana amade athe ngqo TCT Amasuntswana aNgqo

TCT Amasuntswana aNgqo M16 Amasuntswana aNgqo

M16 Amasuntswana aNgqo TCT X Amasuntswana aNgqo

TCT X Amasuntswana aNgqo 45 Isidanga seChamfer Bit

45 Isidanga seChamfer Bit Ukukrola Bit

Ukukrola Bit Bit yeKona

Bit yeKona Amasuntswana omzila wePCD

Amasuntswana omzila wePCD Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander wabona

Edge Bander wabona I-PCD Fine Trimming Cutter

I-PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Ezinye izixhobo kunye nezixhobo

Ezinye izixhobo kunye nezixhobo Drill Adapter

Drill Adapter Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Iimela zokucwangcisa

Iimela zokucwangcisa