introduction

A jointer is a woodworking machine used to produce a flat surface along a board’s length.It is the most common trimming tool.

But how exactly does a jointer work? What are the different types of jointers? And what is the difference between a jointer and a planar?

This article aims to explain the basics of splicing machines, including their purpose, how they work, and how to use them correctly.

Table of Contents

-

What is Jointer

-

How it Work

-

What is Planer

-

Different Between Jointer and Planer

What is jointer

A jointer makes the face of a warped, twisted, or bowed board flat. After your boards are flat, the jointer can be used to straighten square edges

As a jointer, the machine operates on the narrow edge of boards, preparing them for use as butt joint or gluing into panels.

A planer-jointer setup has the width that enables smoothing (surface planing) and leveling the faces (widths) of boards small enough to fit the tables.

Aim:flatten, smooth, and square .corrects material defects

Most woodworking operations can be performed mechanically or manually. A jointer is the mechanical version of a hand tool called a jointer plane.

Component

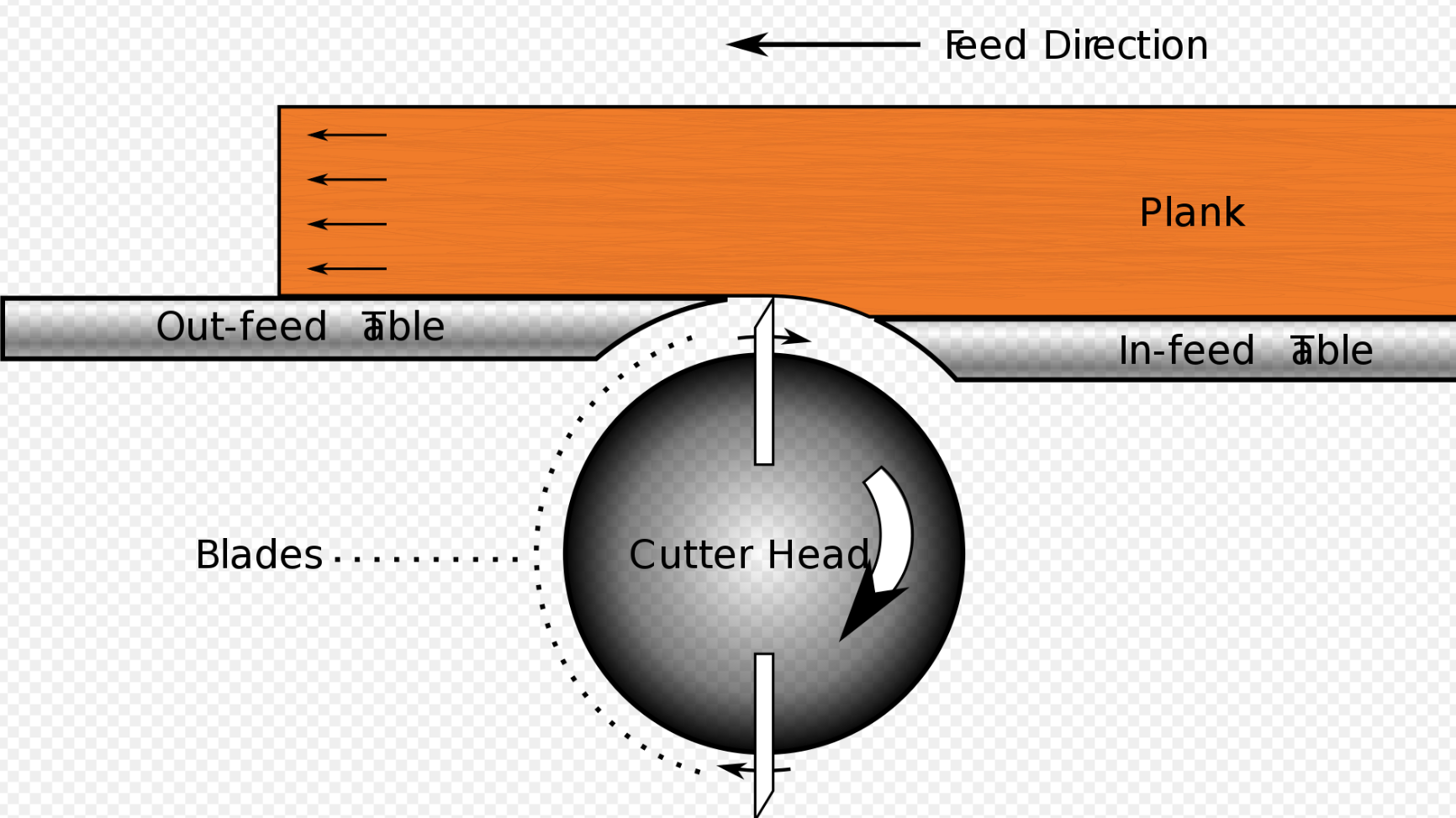

A jointer has four main components: an infeed table, an outfeed table, a fence, and a cutter head.These four components work together to make boards flat and edges square.

A jointer has four main components: an infeed table, an outfeed table, a fence, and a cutter head.These four components work together to make boards flat and edges square.

Fundamentally, a jointer’s table arrangement is designed with two levels like a narrower thickness planer so that it consists of two long, narrow parallel tables in a row with a cutter head recessed between them, but with a side guide.

These tables are referred to as the infeed and outfeed.

As shown in the figure, The infeed table is set slightly lower than the cutterhead .

The cutter head is in the middle of the workbench, and the top of its cutter head is also flush with the outfeed table.

The cutting blades are adjusted to match the height and pitch of (& made square to) the outfeed table.

Safety tip: The outfeed table should never be higher than the cutterhead. Otherwise, boards will stop when they reach the edge).

The infeed and outfeed tables are coplanar, meaning they are on the same plane and are completely flat.

Common size : Jointers for home workshops usually have a 4–6 inch (100–150mm) width of cut. Larger machines, often 8–16 inches (200–400mm), are used in industrial settings.

How it Work

The work piece to be planed flat is placed on the infeed table and passed over the cutter head to the outfeed table, with care taken to maintain a constant feed speed and downward pressure.

The work piece to be planed flat is placed on the infeed table and passed over the cutter head to the outfeed table, with care taken to maintain a constant feed speed and downward pressure.

When it comes to squaring edges, the jointer fence holds the boards at 90° to the cutterhead while the same procedure is performed.

Even though jointers are mostly used for milling, they can also be used for **cutting chamfers, rabbets, and even tapers

Note:Jointers do not create opposite faces and edges that are parallel.

That is the responsibility of a planer.

Safe Use

As with any woodworking tool operation, follow a few guidelines, and check for details before use. It is the only way to ensure your safety

So I’m going to tell you some safety tips

-

MAKE SURE YOUR JOINTER IS PROPERLY SET UP

Make the four parts of jointer,infeed table, outfeed table, fence, and a cutter head.Each is at the right height, as mentioned above.

Also make sure to use push paddles when flattening boards.

-

MARK A BOARD FACE TO FLATTEN

Aim

ecide which face of the board you’re going to flatten.

ecide which face of the board you’re going to flatten.Once you have decided on a face, scribble all over it with a pencil.

The pencil lines will indicate when the face is flat. (pencil gone = flat). -

FEED THE BOARD THROUGH

Begin by placing the board flat on the infeed table and pushing it through the cutterhead with each hand holding a push paddle.

Depending on the length of the board, you may have to move your hands back and forth over each other.

Once enough of the board is past the cutterhead to put a push paddle on, put all the pressure on the outfeed table side.

Continue to push the board through until the blade guard closes and covers the cutterhead.

What is Planer?

Thickness planer (also known in the UK and Australia as a thicknesser or in North America as a planer) is a woodworking machine to trim boards to a consistent thickness throughout their length.

Thickness planer (also known in the UK and Australia as a thicknesser or in North America as a planer) is a woodworking machine to trim boards to a consistent thickness throughout their length.

This machine transcribes the desired thickness using the downside as a reference / index. So, to produce a completely straight planed board requires that the down surface is straight before planing.

Function:

A thickness planer is a woodworking machine to trim boards to a consistent thickness throughout their length and flat on both surfaces.

However the thicknesser has more important advantages in that it can produce a board with a consistent thickness.

Avoids producing a tapered board, and by making passes on each side and turning the board, may also be used for the initial preparation of an unplaned board.

Components:

A thickness planer consists of three elements:

-

a cutter head (which contains the cutting knives); -

a set of rollers (which draw the board through the machine); -

a table (which is adjustable relative to the cutter head to control the resultant thickness of the board. )

How to Work

-

the table is set to the desired height and then the machine is switched on. -

The board is fed into the machine until it makes contact with the in-feed roller: -

The knives remove material on the way through and the out-feed roller pulls the board through and ejects it from the machine at the end of the pass.

Different Between Jointer and Planer

-

Planer Make objects completely parallel or have the same thickness

-

Jointer is a face or straightens and squares an edge,Make things flat

In Terms of Processing Effect

They have different surfacing operation.

-

So if you want an object that is the same thickness but not flat, then you can operate the planner.

-

If you want a material with two flat sides but different thicknesses, continue using joint.

-

If you want a uniformly thick and flat board, place the material in the jointer and then use the planer.

Please note

Make sure to use jointer with caution and follow the details mentioned before to stay safe.

We are koocut tools.

If you are interested,we can provide you best tools.

Pls be free to contact us.

Post time: Jan-18-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives