HERO Cold Saw Blade

Koocut is a saw blade manufacturer in China, Equipped with top-tier German machinery for high-precision welding and grinding, ensuring every tooth delivers peak performance.

With over 25 years of experience in saw blade design and production. On this page, you can quickly explore our cold saw blades and cermet/carbide saw blades for metal dry cutting.

As an integrated manufacturer combining production and research, our saw blade parameters and specifications may differ from other brands. Therefore, please be sure to contact us for product recommendations, technical support, and quotation solutions.

Cold Saw Blades for Sale: We offer retail solutions for non-distributor regions. Just leave us a message here.

Become a Dealer: We provide comprehensive services and support for distributors. Contact us, and our regional business manager will get in touch with you as soon as possible.

Metal Dry Cutting Saw Blade

We offer cermet blades ranging from 100mm to 405mm in diameter for metal dry cutting, which not only deliver superior cutting performance but also ensure the lowest cost per cut.

With years of R&D and manufacturing expertise, we’ve perfected the HERO Wukong dry-cutting solution—from tooth geometry to blade body design—delivering exceptionally strong and long-lasting dry-cut blades.

Versatile Metal Cutting Performance

Our metal cutting blades handle a wide range of materials, including:

✔ Aluminum

✔ Low & medium-carbon steel

✔ Ferrous alloys

✔ Non-ferrous alloys

For maximum blade life and cutting efficiency, always follow the technical guidelines provided by our experts.

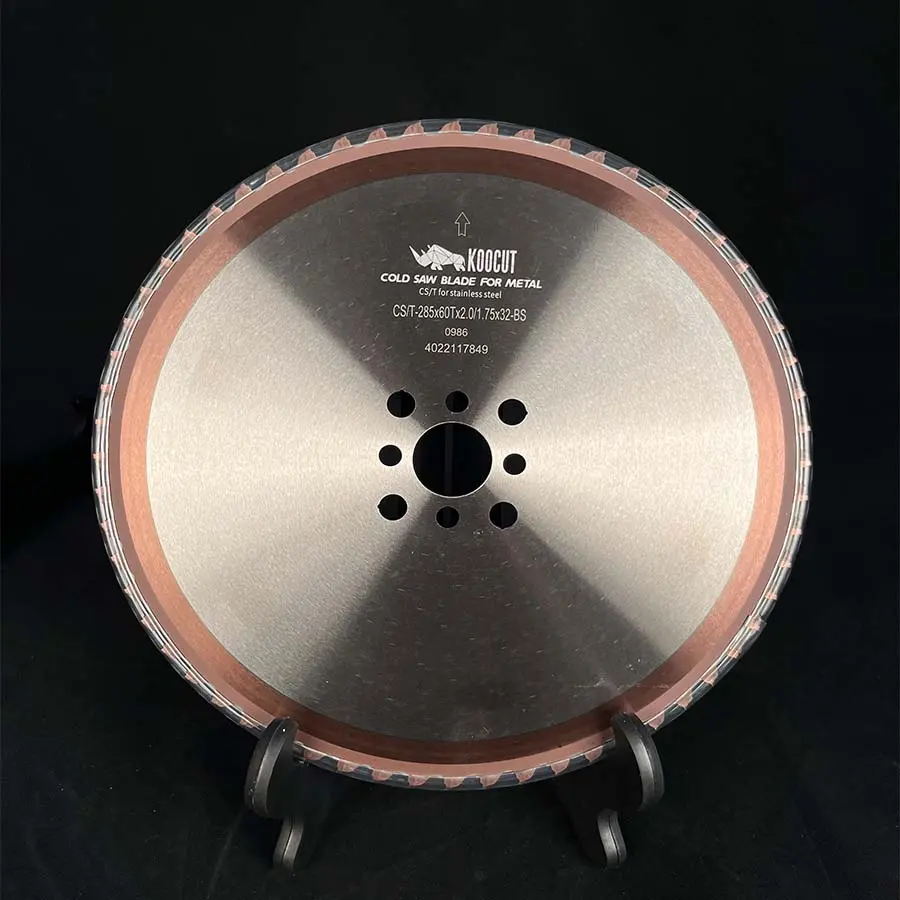

HSS Cold Saw Blade

Leveraging 25+ years of metallurgical expertise, Koocut manufactures premium M2 and M35 HSS cold saw blades for superior performance in dry metal cutting.

Core Technologies:

-

Material Grades:

-

M2 HSS: Optimal balance of hardness/toughness for general carbon steels & alloys.

-

M35 (5% Cobalt): Enhanced red-hardness for continuous cutting of stainless steel, nickel alloys, and high-temp materials.

-

-

Advanced Coatings:

-

TiN (Titanium Nitride): Increased wear resistance for extended blade life in abrasive materials.

-

TiAlN (Titanium Aluminum Nitride): Superior heat resistance (800°C+) for high-speed dry cutting of hardened steels and exotic alloys.

-

Commonly used dimensions and service life table

| Cutting Material | Material | Factory test cutting | Speed(RPM) | Material Size | Site life Cut Square(mm) |

| HRB400 | Rebar | 3225 Times | 1000 | 25MM | 1423900 |

| HRB400 | Rebar | 3250 Times | 1000 | 25MM | 1433720 |

| 45# | Round Steel | 435 Times | 700 | 50MM | 765375 |

| Q235 | square steel pipe | 300 Times | 900 | 80*80*7.75MM | 604800 |

| HRB400 | Rebar | 1040 Times | 2100 | 25MM | 510250 |

| Q235 | Steel Sheet | 45 meter | 3500 | 10MM | 450000 |

| Q235 | Steel Sheet | 42 Meter | 3500 | 10MM | 420000 |

| HRB400 | Rebar | 2580 Times | 1000 | 25MM | 1139120 |

| HRB400 | Rebar | 2800 Times | 1000 | 25MM | 1237320 |

| 45# | Round Steel | 320 Times | 700 | 50MM | 628000 |

| Q235 | square steel pipe | 233 Times | 900 | 80*80*7.75MM | 521920 |

| Q235 | Rectangle tubes | 1200 Times | 900 | 60*40*3MM | 676800 |

| HRB400 | Rebar | 300 Times | 2100 | 25MM | 147300 |

| HRB400 | Rebar | 1500 Times | 1000 | 25MM | 662850 |

Dry Cut Saw Blade Catalog

| Code | Level | Diameter | Tooth | Bore | Tooth Type |

|---|---|---|---|---|---|

| MDB02-110*28T*1.6/1.2*22.23-PJA | 6000 | 110 | 28 | 22.23 | PJA |

| MDB02-140*36T*1.8/1.4*25.4-PJA | 6000 | 140 | 36 | 25.4 | PJA |

| MDB02/S-255*48T*2.0/1.6*25.4-TPD | V5 | 255 | 48 | 25.4 | TPD |

| MDB02/S-255*48T*2.0/1.6*25.4-TPD | 6000 | 255 | 48 | 25.4 | TPD |

| MDB02-140*36T*1.8/1.4*34-PJA | 6000 | 140 | 36 | 34 | PJA |

| MDB02/S-355*66T*2.2/1.8*25.4-TP | 6000 | 355 | 66 | 25.4 | TP |

| MDB02-110*28T*1.6/1.2*22.23-PJA | V5 | 110 | 28 | 22.23 | PJA |

| CDB02/S-255*48T*2.0/1.6*25.4-TPD | 6000 | 255 | 48 | 25.4 | TPD |

| MDB02/S-355*80T*2.2/1.8*25.4-TP | 6000 | 355 | 80 | 25.4 | TP |

| MDB02/S-255*52T*2.0/1.6*25.4-TP | 6000 | 255 | 52 | 25.4 | TP |

| MDB02/S-355*66T*2.2/1.8*25.4-TP | V5 | 355 | 66 | 25.4 | TP |

| MDB02-185*36T*1.8/1.4*20-TPA | 6000 | 185 | 36 | 20 | TPA |

| MDB02-140*36T*1.8/1.4*34-PJA | 6000 | 140 | 36 | 34 | PJA |

| MDB02/S-355*80T*2.2/1.8*25.4-TP | V5 | 355 | 80 | 25.4 | TP |

| CDB02-125*24T*1.6/1.2*20-PJA | 6000 | 125 | 24 | 20 | PJA |

| MDB02/S-305*60T*2.2/1.8*25.4-TP | V5 | 305 | 60 | 25.4 | TP |

| MDB02/S-185*36T*1.8/1.4*20-PJAD | 6000 | 185 | 36 | 20 | PJAD |

| CDB02-185*32T*1.8/1.4*20-BC | 6000 | 185 | 32 | 20 | BC |

| MDB02/S-405*96T*2.8/2.4*30-TP | V5 | 405 | 96 | 30 | TP |

| MDB02-185*32T*1.8/1.4*20-BC | 6000 | 185 | 32 | 20 | BC |

| CDB02/S-305*80T*2.2/1.8*25.4-TP | V5 | 305 | 80 | 25.4 | TP |

| MDB02/S-305*60T*2.2/1.8*25.4-TP | 6000 | 305 | 60 | 25.4 | TP |

| MDB02/S-305*80T*2.2/1.8*25.4-TP | V5 | 305 | 80 | 25.4 | TP |

| MDB02/S-405*96T*2.8/2.4*25.4-TP | V5 | 405 | 96 | 25.4 | TP |

| MDB02/S-230*48T*2.0/1.6*25.4-TPD | 6000 | 230 | 48 | 25.4 | TPD |

| MDB02/S-405*96T*2.8/2.4*32-TP | V5 | 405 | 96 | 32 | TP |

| MDB02-145*36T*1.8/1.4*22.23-PJA | 6000 | 145 | 36 | 22.23 | PJA |

| MDB02/S-255*48T*2.0/1.6*32-TPD | V5 | 255 | 48 | 32 | TPD |

| CDB02/S-355*80T*2.2/1.8*25.4-TP | V5 | 355 | 80 | 25.4 | TP |

| MDB02/S-305*80T*2.2/1.8*25.4-TP | 6000 | 305 | 80 | 25.4 | TP |

| CDB02-150*40T*1.6/1.2*20-PJA | 6000 | 150 | 40 | 20 | PJA |

| MDB02/S-230*48T*2.0/1.6*25.4-TP | 6000 | 230 | 48 | 25.4 | TP |

| MDB02/S-255*48T*2.0/1.6*25.4-TPD | 6000 | 255 | 48 | 25.4 | TPD |

| CDB02/S-355*66T*2.2/1.8*25.4-TP | 6000 | 355 | 66 | 25.4 | TP |

| MDB02/S-405*72T*2.8/2.4*32-TP | 6000 | 405 | 72 | 32 | TP |

| MDB02/S-355*66T*2.2/1.8*32-TP | 6000 | 355 | 66 | 32 | TP |

| MDB02/S-405*72T*2.8/2.4*25.4-TP | 6000 | 405 | 72 | 25.4 | TP |

| CDB02/S-355*80T*2.2/1.8*25.4-TP | 6000 | 355 | 80 | 25.4 | TP |

| MDB02/S-255*52T*2.0/1.6*25.4-TPD | 6000 | 255 | 52 | 25.4 | TPD |

| MDB02/S-405*96T*2.8/2.4*25.4-TP | 6000 | 405 | 96 | 25.4 | TP |

| CDB02-165*52T*1.2/1.0*20-TP | V5 | 165 | 52 | 20 | TP |

| MDB02/S-355*116T*2.2/1.8*25.4-TP | 6000 | 355 | 116 | 25.4 | TP |

| CDB02/S-255*52T*2.0/1.6*25.4-TP | 6000 | 255 | 52 | 25.4 | TP |

| MDB02/S-255*52T*2.0/1.6*25.4-TPD | V5 | 255 | 52 | 25.4 | TPD |

| MDB02/S-305*60T*2.2/1.8*25.4-TP | 6000 | 305 | 60 | 25.4 | TP |

| CDB02/S-255*60T*2.0/1.6*32-TP | 6000 | 255 | 60 | 32 | TP |

| MDB02/S-405*96T*2.8/2.4*32-TP | 6000 | 405 | 96 | 32 | TP |

| MDB02/S-255*80T*2.0/1.6*32-TP | 6000 | 255 | 80 | 32 | TP |

| MDB02/S-405*96T*2.8/2.4*30-TP | 6000 | 405 | 96 | 30 | TP |

| MDB02/S-185*36T*2.0/1.6*20-TP | V5 | 185 | 36 | 20 | TP |

| MDB02/S-355*66T*2.2/1.8*25.4-TP | 6000 | 355 | 66 | 25.4 | TP |

| CDB02/S-355*66T*2.2/1.8*25.4-TP | V5 | 355 | 66 | 25.4 | TP |

| CDB02-110*24T*1.6/1.2*20-PJA | 6000 | 110 | 24 | 20 | PJA |

| CDB02/S-305*80T*2.2/1.8*30-TP | V5 | 305 | 80 | 30 | TP |

| MDB02/S-230*48T*1.9/1.6*25.4-TP | 6000 | 230 | 48 | 25.4 | TP |

| MDB02/S-355*80T*2.2/1.8*25.4-TP | V5 | 355 | 80 | 25.4 | TP |

| MDB02/S-305*60T*2.2/1.8*32-TP | V5 | 305 | 60 | 32 | TP |

| MDB02/S-600*100T*3.6/3.0*32-TP | 6000 | 600 | 100 | 32 | TP |

| CDB02-110*28T*1.6/1.2*22.23-PJA | 6000 | 110 | 28 | 22.23 | PJA |

| CDB02/S-405*96T*2.8/2.4*32-TP | 6000 | 405 | 96 | 32 | TP |

| CDB02/S-255*48T*2.0/1.6*30-TPD | V5 | 255 | 48 | 30 | TPD |

| CDB02/S-355*80T*2.2/1.8*25.4-TP | V5 | 355 | 80 | 25.4 | TP |

| MDB02/S-355*80T*2.2/1.8*32-TP | 6000 | 355 | 80 | 32 | TP |

| MDB02/S-405*96T*2.8/2.4*32-TP | V5 | 405 | 96 | 32 | TP |

| MDB02/S-355*100T*2.2/1.8*25.4-TP | 6000 | 355 | 100 | 25.4 | TP |

| CDB02/S-305*60T*2.2/1.8*25.4-TP | V5 | 305 | 60 | 25.4 | TP |

| MDB02/S-455*80T*2.8/2.4*25.4-TP | V5 | 455 | 80 | 25.4 | TP |

| MDB02/S-405*72T*2.8/2.4*32-TP | V5 | 405 | 72 | 32 | TP |

| CDB02-115*20T*1.6/1.2*20-PJA | 6000 | 115 | 20 | 20 | PJA |

| CDB02/S-255*80T*2.0/1.6*25.4-TP | V5 | 255 | 80 | 25.4 | TP |

| CDB02/S-355*80T*2.2/1.8*30-TP | V5 | 355 | 80 | 30 | TP |

| CDB02/S-255*80T*2.0/1.6*30-TP | V5 | 255 | 80 | 30 | TP |

| MDB02-185*32T*1.8/1.4*20-BC | 6000 | 185 | 32 | 20 | BC |

| MDB02/S-455*84T*3.6/3.0*25.4-TP | 6000 | 455 | 84 | 25.4 | TP |

| MMB02/S-355*100T*2.2/1.8*25.4-TP | V5 | 355 | 100 | 25.4 | TP |

| MDB02/S-355*66T*2.2/1.8*25.4-TP | V6 | 355 | 66 | 25.4 | TP |

| MDB02-150*40T*1.6/1.2*20-PJA | V5 | 150 | 40 | 20 | PJA |

| MDB02/S-405*72T*2.8/2.4*25.4-TP | V5 | 405 | 72 | 25.4 | TP |

| CDB03-165*36T*1.8/1.4*20-TPE | 6000 | 165 | 36 | 20 | TPE |

| MDB02-145*36T*1.8/1.4*22.23-PJA | 6000 | 145 | 36 | 22.23 | PJA |

| MDB02/S-405*80T*2.8/2.4*25.4-TP | 6000 | 405 | 80 | 25.4 | TP |

| MDB02/S-305*80T*2.2/1.8*25.4-TPD | 6000 | 305 | 80 | 25.4 | TPD |

| MDB02-185*36T*1.8/1.4*25.4-TPA | 6000 | 185 | 36 | 25.4 | TPA |

| MDB02/S-255*52T*2.0/1.6*25.4-TPD | V5 | 255 | 52 | 25.4 | TPD |

| MDB02/S-305*80T*2.2/1.8*25.4-TP | V5 | 305 | 80 | 25.4 | TP |

| CDB02/S-185*36T*1.8/1.4*20-BCD | 6000 | 185 | 36 | 20 | BCD |

| MDB02/S-230*48T*2.0/1.6*25.4-TP | 6000 | 230 | 48 | 25.4 | TP |

| MDB02/S-355*116T*2.2/1.8*30-TP | 6000 | 355 | 116 | 30 | TP |

| MDB02/S-355*100T*2.2/1.8*30-TP | 6000 | 355 | 100 | 30 | TP |

| MDB02/S-455*84T*2.8/2.4*25.4-TP | 6000 | 455 | 84 | 25.4 | TP |

| MDB02/S-405*72T*2.8/2.4*40-TP | 6000 | 405 | 72 | 40 | TP |

| MDB02/S-255*54T*2.0/1.6*25.4-TPD | 6000 | 255 | 54 | 25.4 | TPD |

| MDB02/S-355*80T*2.2/1.8*30-TP | 6000 | 355 | 80 | 30 | TP |

| MDB02/S-355*66T*2.2/1.8*30-TP | 6000 | 355 | 66 | 30 | TP |

| MDB02/NS-600*100T*3.6/3.0*35-TP | V5 | 600 | 100 | 35 | TP |

FAQ

Founded in 1999, HERO has over 25 years of experience in designing, developing, and manufacturing cutting tools in China. Recognized by the market for outstanding cutting efficiency, performance, and blade longevity, HERO now supplies high-quality saw blades to customers worldwide.

Koocut is a cutting tools production factory invested in and built by HERO. Equipped with advanced automated manufacturing facilities and management systems, it is dedicated to manufacturing saw blades for HERO.

These blades are factory-ready and can be shipped immediately—no production wait time.

Whether for simple cutting tasks or high-intensity continuous work, we have the right blade models to optimize both your cutting performance and cost efficiency.

Don't find saw blades you need? Please contact us and we will make your special cutting blades

We offer blade sharpening services, but this incurs additional logistics costs, and resharpened blades often fail to perform at their best. When you do the math, you'll find that purchasing multiple blades upfront is more cost-effective—not only do you get a better price per blade, but you also save on logistics expenses compared to repeated sharpening.

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives