introduction

In construction and manufacturing, cutting tools are indispensable.

Chop Saw, Miter Saw and Cold Saw represent three common and efficient cutting tools. Their unique designs and working principles make them play a key role in different cutting tasks.

Only with the correct cutting tool capable of providing precise and rapid cuts without distorting the material is precise and fast cutting possible. Three of the most popular saw blade; choosing between them might be difficult.

This article will take an in-depth look at these three cutting tools, analyze their similarities and differences, and reveal their advantages in practical applications to help readers better understand how to choose a cutting tool suitable for their work needs.

Table of Contents

-

Miter saw

-

Cold saw blade

-

Chop saw

-

Different

-

Conclusion

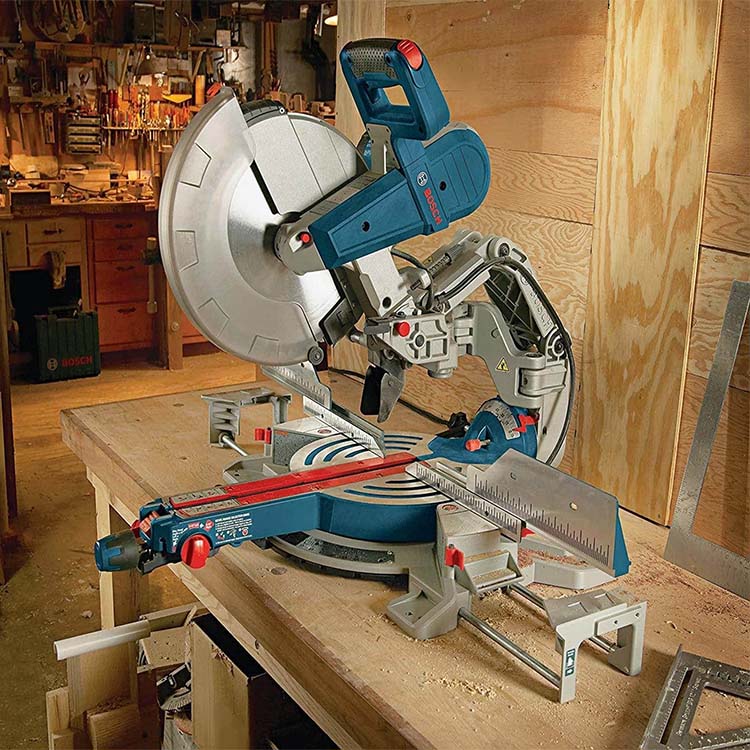

Miter saw

A miter saw, also known as a mitre saw, is a type of saw used for making accurate crosscuts, miters, and bevels in a workpiece. It consists of a circular saw blade mounted on a swinging arm that can pivot to make miter cuts at various angles. Depending on the model, it may also be able to make bevel cuts by tilting the blade

The blade is pulled downwards onto the material, unlike with a circular saw where it feeds through the material.

They are primarily used for cutting wood trim and molding, but also can be used to cut metal, masonry, and plastics, provided the appropriate type of blade is used for the material being cut.

Size

Miter saws come in a variety of sizes. The most common sizes are 180, 250 and 300 mm (7+1⁄4, 10 and 12 in) size blades, each of which has its own cutting capacity.

Miter saws commonly come in 250 and 300 mm (10 and 12 in) blade size configurations and are commonly made of carbon steel and may come with a coating to make the cut easier.

Tooth Shape

Teeth design comes in many variations: ATB (alternating top bevel), FTG (flat top grind) and TCG (triple chip grind) are the most common. Each design is optimized for a specific material and edge treatment.

Usage

The saw is Commonly used with Wood,and can be found in various models and sizes.

Miter saws are capable of making straight, miter, and bevel cuts.

Type

here is a huge range of mitre saws available on the market. Single bevel, double bevel, sliding, compound etc.

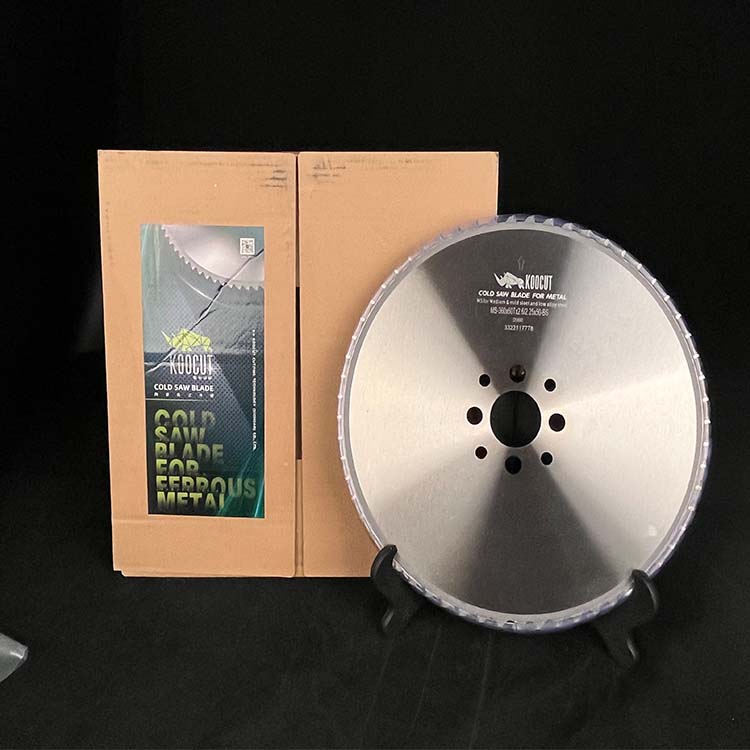

Cold saw

A cold saw is a circular saw designed to cut metal which uses a toothed blade to transfer the heat generated by cutting to the chips created by the saw blade, allowing both the blade and material being cut to remain cool.This is in contrast to an abrasive saw, which abrades the metal and generates a great deal of heat absorbed by the material being cut and saw blade.

Application

Cold saws are capable of machining most ferrous and non-ferrous alloys. Additional advantages include minimal burr production, fewer sparks, less discoloration and no dust.

Saws designed to employ a flood coolant system to keep saw blade teeth cooled and lubricated may reduce sparks and discoloration completely. Saw blade type and number of teeth, cutting speed, and feed rate all must be appropriate to the type and size of material being cut, which must be mechanically clamped to prevent movement during the cutting process.

But there is a type of cold saw that does not require coolant.

Type

Cermet cold saw blades

Dry Cut Cold Saws

Cermet Cold Saw Blade

A Cermet HSS Cold Saw is a type of saw that uses blades made from high-speed steel (HSS), carbide, or cermet to perform cutting operations. Cermet-tipped cold saw blades are designed for high-production cutting of billets, pipes, and various steel shapes. They are engineered with a thin kerf and are known for their exceptional cutting performance and extended blade life.

Suitable Machinery: Large cold saw machine

Dry Cut Cold Saw

Dry cut cold saws are known for their accuracy, producing clean and burr-free cuts, which reduce the need for additional finishing or deburring work. The absence of coolant results in a cleaner work environment and eliminates the mess associated with traditional wet cutting methods.

Key features of dry cut cold saws include their high-speed circular blades, often equipped with carbide or cermet teeth, which are specifically engineered for metal cutting. Unlike traditional abrasive saws, dry cut cold saws operate without the need for coolant or lubrication. This dry cutting process minimizes heat generation, ensuring that the structural integrity and properties of the metal remain intact.

A cold saw produces precise, clean, milled finish cuts, whereas a chop saw may wander and produce a finish that usually necessitates a subsequent operation to de-burr and square-up after the item cools down. Cold saw cuts may usually be moved down the line without requiring a separate operation, which saves money.

Suitable machinery: Metal Cold Cutting Saw

While a cold saw isn’t as much fun as a chop saw, it produces a smooth cut that allows you to finish the task quickly. It is no longer necessary to wait for your material to cool after it has been cut.

Chop saw

Abrasive saws are a type of power tool that use abrasive discs or blades to cut through various materials, such as metals, ceramics, and concrete. Abrasive saws are also known as cut-off saws, chop saws, or metal saws.

Abrasive saws work by rotating the abrasive disc or blade at a high speed and applying pressure to the material to be cut. The abrasive particles on the disc or blade wear away the material and create a smooth and clean cut.

Size

The cutting disk is typically 14 in (360 mm) in diameter and 764 in (2.8 mm) in thickness. Larger saws can employ discs with a diameter of 16 in (410 mm).

Different

Cutting ways:

Cold saw,Chop saws make straight crosscuts only.

Miter saws are capable of making straight, miter, and bevel cuts.

A common misnomer that is sometimes used to refer to a miter saw is the chop saw. Although somewhat similar in their cutting action, they are two entirely different types of saw. A chop saw is specifically meant to cut metal and is typically operated while laid flat on the ground with the blade fixed at 90° vertical. A chop saw cannot make a miter cut unless manipulated by the operator as opposed to the function of the machine itself.

Application

A miter saw is ideal for cutting wood.

Unlike table saws and band saws,they are excellent when it comes to cutting materials like dimensional lumber for framing, decking, or flooring.

Cold saw and chop saw is for metal cutting,but the cold saw can cut A wider variety of materials more than chop saw.

And cutting is more fast

Conclusion

As a versatile and efficient cutting tool, the Chop Saw excels in directly cutting a variety of materials. Its simple yet powerful structure makes it widely used in construction sites and other scenarios.

The Miter Saw’s flexibility in angle adjustment and bevel cutting is a significant advantage, making it ideal for woodworking and decorative work. Its design allows users to easily create various angles and bevel cuts.

Cold Saw is unique in the field of metal cutting with its cold cutting technology. The use of cold cutting technology not only increases the cutting speed, but also ensures high-precision cutting results, which is especially suitable for scenes that require high material performance.

If you are interested,we can provide you best tools.

Post time: Dec-30-2023

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives