How do you cut with a panel saw without blowout?

A panel saw is any type of sawing machine that cuts sheets into sized parts.

Panel saws can be vertical or horizontal. Typically, vertical saws take up less floor space.

Horizontal machines are typically large table saws with a sliding feed table that pushes the material through the blade. Table saws without the sliding feed table can also cut sheet goods.

Vertical saws have two cost types, low cost and higher cost. Both types have the saw traveling through the short side of the sheet called cross cutting. For cutting lengthwise (rip) cut, the lower cost models, have the user slide the material through the saw while the higher cost models have the saw travel through the stationary material.

A sliding panel saw was invented by Wilhelm Altendorf in 1906 in Germany.Its invention set a new standard in woodworking, with dramatic differences from traditional machines.Up to that time, a conventional table saw had no mechanism for edging, meaning that for the first and second longitudinal cut on untreated massive wood, the lumber always had to be fed manually through the saw blade. The new system accomplished the task more elegantly by allowing the work piece to be fed through the saw blade while lying on a sliding table. Thus cutting becomes faster, accurate and effortless.

Panel saws are used by cabinet shops to easily cut panels, profiles, solid wood, plywood, MDF, laminates, plastic sheets and melamine sheets into sizes or cabinet components. They are also used by sign shops to cut sheets of aluminum, plastic and wood for their sign blanks. Some higher end panel saws feature computer controls that move the blade and fence systems to preset values. Other lower end machines offer simplicity and ease of use, including full scale hobbyist level panel saws at a mere fraction of the cost. While the entry level machines are designed for light duty usage, they offer home DIYers a cheap alternative for infrequent cutting when accuracy and clean cuts are not required.

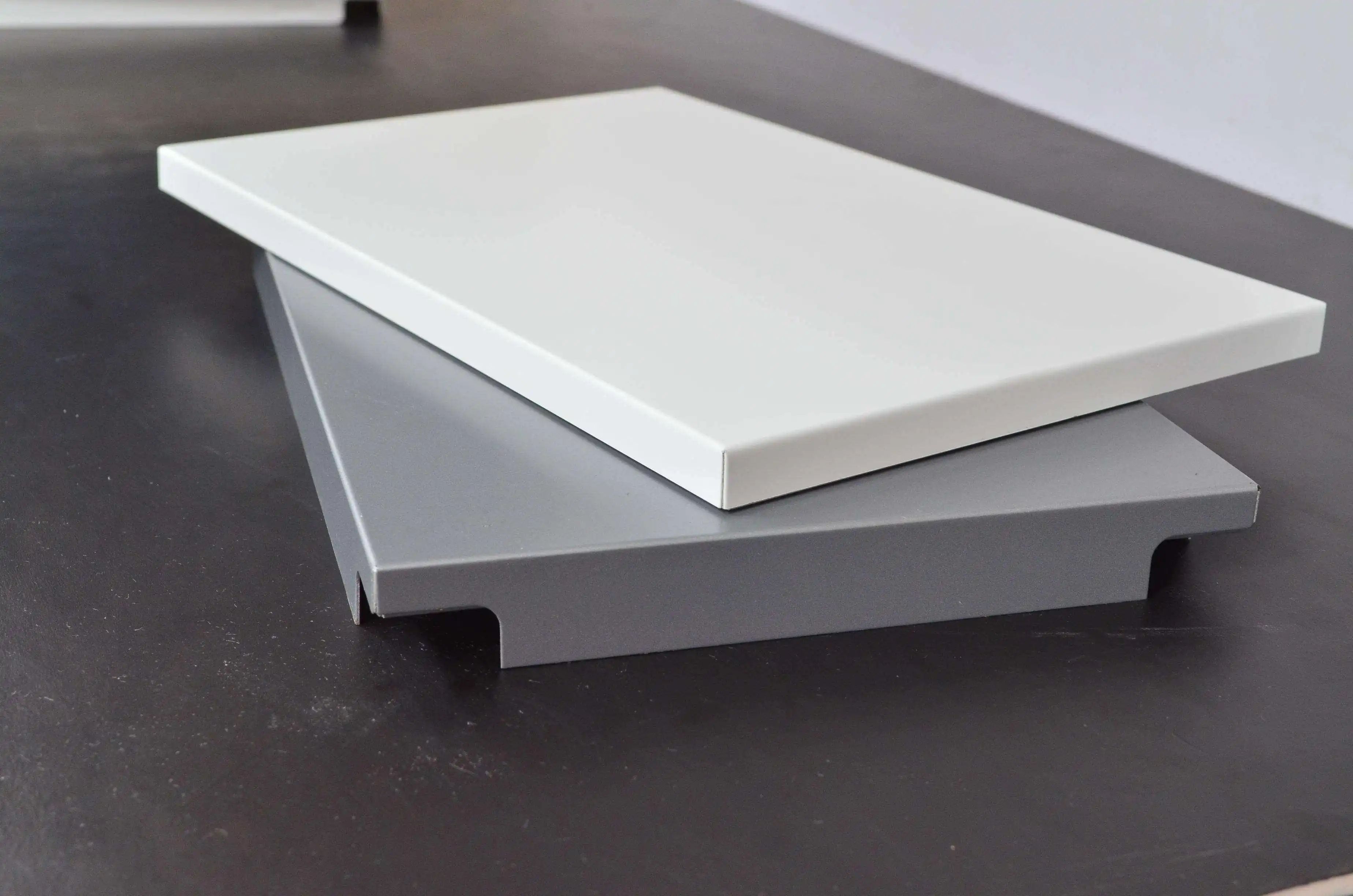

Panel saws can have one main saw blade, or a scoring along with a main saw blade. Scoring is used to create a groove, especially in double side laminate before the main saw rips the piece in two, to avoid chipping. The scoring saw rotates in an opposite direction, as the main saw to avoid chipping.

Main Differences Between a Panel Saw and Table Saw

When comparing a panel saw to a table saw there are a few key differences with the main being versatility when working with large sheets of materials. A typical vertical panel saw has a saw blade that is mounted on a slider that runs along guide tubes to easily make vertical cross cuts as well as rotate 90 degrees for rip cuts. A panel saw can also support a wooden panel vertically along a channel of rollers allowing for easier material handling. In contrast, a conventional table saw is able to make the same rip and crosscuts, but also beveled and angled cuts. A regular table saw is significantly more versatile than a panel saw however if you’re working with large sheet goods a panel saw allows for one person to easily break down full sheets of plywood easily and is safer.

Which is Better a Panel Saw or a Table Saw?

To determine which is better a panel saw or a table saw, you need to figure out your needs, and depends on the individual woodworker. A table saw is an essential tool for most woodworking shops and DIY woodworkers and is capable of crosscuts and rip cuts on large sheets of wood, especially the large table saws paired with an outfeed table. I personally use a full 4×8 foot outfeed table and roller supports to break down plywood on my table saw. However, I only need to cut large panels on a few occasions and panel saws have a very large footprint and are quite expensive. Although, vertical panel saws are great for larger shops or cabinet makers that need to process plywood sheets on a daily basis. Panel saws are better than table saws and are ideal for cutting large sheets of plywood in a commercial workshop.

Panel Saw Advantages

The main advantage of a panel saw is that you can easily handle large pieces of wood panels with one person safely. It only takes a few inches to lift the sheet materials onto the roller channel and eliminates any risk of kickback with a fumbled panel. Also, panel saws can make unlimited rip cuts with ease by sliding the panel through the saw blade without having to lift the panel. If you’re processing a lot of sheet goods a panel saw makes quick work of vertical and horizontal cuts and could save you a considerable amount of time and money.

Panel Saw Disadvantages

One of the main disadvantages of a panel saw is the initial cost of the new saw and the limited versatility. A panel saw is very limited in that it can’t cut angles or bevels which would have to be done on a table saw. Also, adding a panel saw would take up quite a bit of space in your workshop, and depending on the panel saw they are not portable for job site construction.

Table Saw Advantages

The main advantages of table saws are they are affordable and can be used for countless functions including breaking down panels. A table saw is a perfect choice if you want to cut more than standard 90-degree crosscuts and rip cuts on sheet goods. A table saw is also able to rip solid wood due to having much higher hp motors than a panel saw. Also, job site table saws are portable and easily stored away for DIY woodworkers.

Table Saw Disadvantages

Unless you have a large sliding table saw or a cabinet saw with additional work supports, breaking down a full plywood sheet is difficult. I have on occasion made rip cuts on a full sheet of plywood on my hybrid table saw but wouldn’t recommend it if you need to do it regularly. Also, one major downside of a table saw is safety, with a lot of injuries and accidents by accidental contact with a spinning blade. Realistically one person can’t have control over large pieces on a table saw, increasing the risk of a kickback or injury.

What should you do if there are burst edges when processing boards with a panel saw?

When cutting boards with saw blades, there are two situations where edge bursting will occur: main saw blade (large saw blade bursting edge); groove saw (bottom saw edge bursting)

-

The saw blade vibrates too much

If the saw blade vibrates too much during operation, the contact surface between the drive shaft and the machine can be adjusted, causing the vibration to be transmitted. When the machine is cutting materials normally, no harsh cutting sound will be heard.

-

Bearing damage

During the long-term operation of the machine, the bearings are damaged due to vibration or dust, or due to wear of the rubber clamping ring outside the fixed bearing. How to check: You can tell by listening to the sound when you first start or end the machine.

-

The shaft bends during use

Workers sometimes do not understand the direction of the up and down saw blades when disassembling the saw blades, or do not take out the hexagonal wrench of the main saw in time when installing the saw blades, resulting in deformation of the shaft.

-

The influence of different plates

Normally when sawing melamine boards, the resistance of the saw blade is relatively large when thick boards (thickness is relatively thick, 2.5cm, 5cm), and the saw blade needs to be adjusted lower to reduce vibration.

-

Reasons for scribing saws

The board is arched, causing the scribing saw not to contact the board. When the scribing saw is raised too high, it vibrates and affects the saw material; the scribing saw is not sharp; the scribing saw and the main saw are not in line; the scribing saw and the main saw are not in line with the ground. The angles are inconsistent, resulting in excessive resistance and edge explosion;

Post time: Apr-19-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives