How to Cut a 45 degree Angle with a Circular Saw?

What is steel angle?

Steel angle, also named angle iron, or steel angle bar, is basically manufactured by hot-rolled carbon steel or high strength low alloy steel. It has L-cross shaped section with two legs – equal or unequal and the angle would be 90 degree. steel angles are finished steel products made through hot-forming semi-finished carbon steel. As steel angles are mainly used for providing structural support, the most ideal composition is a low alloy, yet high strength steel with better ductility and toughness. With this in mind, the different uses of steel angles can vary from bridge ways, warehouses, equipment manufacturing, support frames, shelves, or even utility carts.

Although steel angles are considered to be the most basic version of any roll-formed steel, they offer excellent advantages, especially when it comes to framing, reinforcement, aesthetic trims, brackets, and the like. Combined with the inherent properties of low-alloy steel, these angle bars have been a reliable assembly part or construction material, depending on the use. Read on to learn more.

What are the uses of steel angles?

-

1.Bridge ways -

2.Warehouses -

3.Equipment manufacturing -

4.Frames

Bridge ways

Steel angles are rarely used in a given structure without any added protective layer or coating. As such, most steel angles you’ll find in the market are either galvanized or powder coated. Galvanizing creates a corrosion-resistant layer on the material, while powder coating is a form of surface finish made out of electrostatic-spray deposited (ESD) resins. When used in bridge ways, however, manufacturers need to ensure better product durability, which is why the angle bars are galvanized in the process.

Steel angles can be used to form any part of a bridge. For the deck, the angles can provide reinforcement to concrete and lower materials handling for constructors. Aside from this, steel angles can also be found in bridge components like arches, girders, bearings, or pedestrian pathways. Bridges with steel components have been known to last for several years or even decades, due to the material’s robustness and strength even under load bearing or environmentally impactful situations.

Warehouses

As established, steel angle bars are a type of structural product. For warehouses or any type of building construction, steel angles have been a perfect choice. They can form the foundation of a warehouse, complete the structure of a mezzanine system, or provide roofing support through a steel deck or rafter.

For mezzanines, steel angles can support the elevated flooring requirements of the structure. The material is well-suited for bearing different levels of loads or impacts that may arise from equipment and storage systems used in the warehouse. This stands true even for various mezzanine designs — freestanding, rack-supported, column-connected, or shelving-supported mezzanines.

In low-cost warehouses, steel angles have also been useful in forming part of the ceiling or roofing structure of the building. When connected with other steel accessories — flat bars, rods, couplings, purlins, fittings — the steel angles can complete the network of rafters that protect the warehouse from variable wind loads.

Equipment Manufacturing

Most electrical equipment or everyday household appliances to date have been made out of one form of steel or another. Some examples of these heavy machineries include the forklift, bulldozer, road roller, or excavators. Appliances may even be reinforced with steel angles — their unique shape gives protection to corners of appliances like washing machines, industrial ovens, stoves, and many more.

Using steel angles in equipment-making has drastically lowered expenses for both manufacturer and consumer. Manufacturers, for example, are relying on a low-cost and easy-to-produce material. Steel is also considered readily available and can be repurposed without any detriment in its chemical properties and physical quality.

For consumers, steel in different types of machinery greatly lowers maintenance and repair costs. As mentioned before, steel can last for many decades, even during storage. Businesses that depend on heavy equipment in their operations will benefit from the presence of steel angles, even if they may be aware of it or not.

Frames

Steel angles have been purposely made to be ductile. This is made possible by their low-alloy/high strength composition that creates a highly malleable material, capable of being shaped and fabricated using various techniques.

Another popular use of steel angles is framing for different structures and objects. While the basic design involves an equal (or non-equal) angled L-shaped cross-section featuring two opposing legs, it can be fabricated to attain the desired appearance.

Metal stamping or punching, in particular, can create multiple openings on a steel angle to create an aesthetically pleasing framing component. Other custom-built designs can also be done on steel angle framing to support handrails, utility carts, interior moldings, trimmings, paneling, cladding, and many more.

Steel angles or angle bars are some of the most widely-used materials in construction.Despite its simplistic design, it has proven to be a reliable component for different industries. Alongside other steel products, the steel angle continues to be used wherever durability and structural integrity are required.

Many people want to know can a circular saw cut metal?

The answer is: it depends. You have a lot of factors to consider in the metal-cutting vs circular saw question—like blade speed, the blade itself, and the collection of metal shavings created by the blade. You may look at your circular saw and wonder, “Why buy a metal saw when a framing saw does the same job?”

It’s a fair question and, actually, you could do that. Plenty of manufacturers make 7-1/4-inch metal cutting blades that will fit a standard circular saw. However, even the best circular saws fall short when you start comparing features specifically tailored toward metal-cutting applications.

Metal cutting saws differ from standard circular saws in the following ways:

-

Lower RPMs to cut more efficiently in metal -

Optional debris collectors to catch metal shavings (some models) -

Smaller blade sizes further reduce RPMs and allow for more control -

Closed housings to better control debris

Cutting metal presents a more difficult task than cutting wood. Metal cutting more closely resembles abrasion than chipping away large particles of material. 7-1/4-inch blades create a lot of sparks when they cut metal at high speed. That equals flying, flaming hot metal shards that can wear out a blade quickly.

The design of metal-cutting saws lets them either collect or deflect those shards better than a framing circular saw. Finally, but more generally, a traditional wood-cutting circular saw’s open housing might not protect against metal shard buildup. Metal-cutting saws typically have closed housings for that purpose.

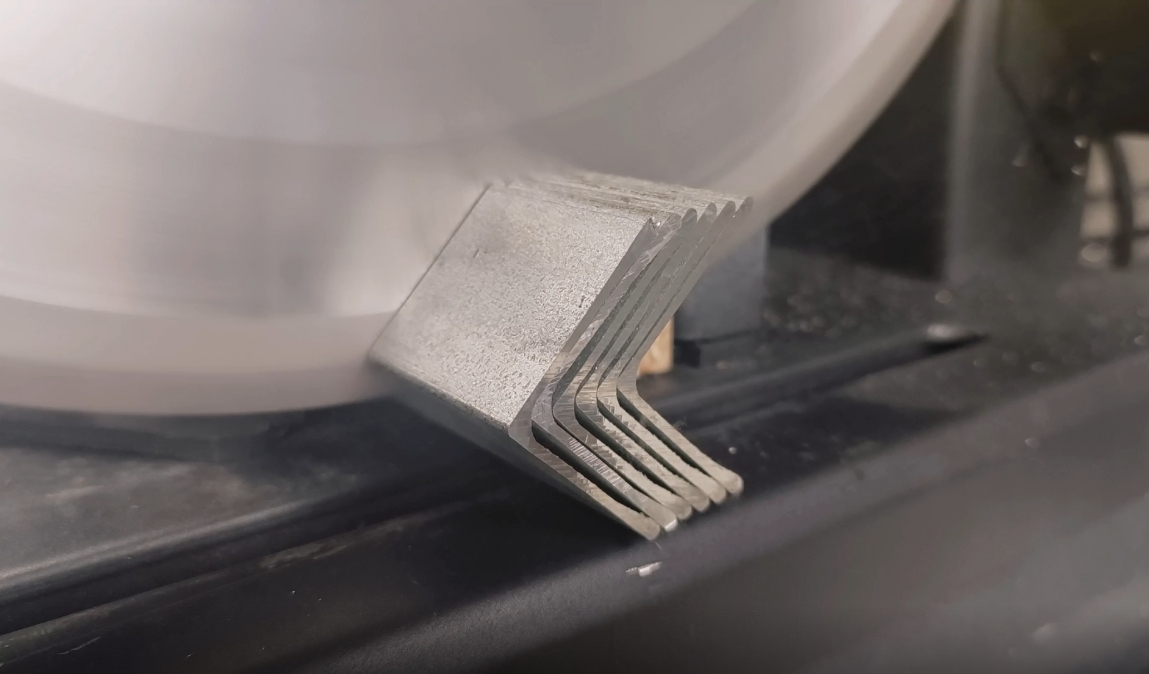

There are several ways to cut angle iron to size when required, including a torch, an angle grinder with a cutoff wheel or a chop saw. If you are doing several cuts in a row, mitered cuts or need absolute precision, the cop saw is the best choice.

Post time: Mar-22-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives