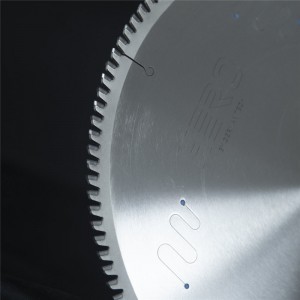

PCD German Technology High Quality Circular Saw Blade for Aluminum

Product Overview

Raw Materials: PCD segment, German imported steel plate 75CR1 and Japan imported steel plate SKS51.

Brand: HERO, LILT

Features

1. A cutting method for aluminum materials such aluminum profiles, heat-insulating aluminum saw blades, aluminum rod, etc.

2. Used on various devices, including table saws and portable saws.

3. Silent design with Japanese damping and chrome plating. cutting even more noiseless quiet.

4. The PCD sector claimed longer tool operating lives and the ability to extend blade life.

5. Vibration is reduced and optimum performance is promoted by the anti-vibration design.

6. Utilizing sandwich silver-copper-silver technology and Gerling machines to complete the teeth brazing procedure.

7. To complete the grinding process, which is the most crucial step for PCD saw blades, use a copper electronic sanding wheel.

8. PCD teeth are typically 6.0mm long, although they can be modified to certain lengths, such as 6.8mm.

Parameters

The high quality PCD saw blades for cutting of non ferrous metals (aluminum engine blocks, cylinder heads, aluminum wheels, etc.) are of high-performing, precision engineered, achieves much longer cutting life. Proprietary brazing techniques help prevent PCD tips loss from impact.

PCD saw bodies are subjected to many forces in cutting which cause vibration and harmonic resonance. IBISE has developed special saw body designs to absorb vibration and reduce resonance providing a more stable, smother, quieter and longer lasting cutting life. Swarf adhesion is very damaging to metal cutting saws, especially diamond saws. We make the special tooth designs encourage proper swarf waste transfer away from the cut enhancing blade longevity while improving cut quality.

This PCD saw blades are mainly used for high precision cutting process on non ferrous metals, such as aluminium engine blocks, cylinder heads, aluminium wheels, etc. All PCD saw blades are carried to perfect heat treatment, dynamic balance and tensioning to ensuring premium results.

PCD saw blades have extraordinary wear resistance, with a longer tool life, reduce the repair times and enhanced product quality. Longer tool life amplifies production capacity resulting in increased machine up-time and superior work piece quality along with consistent surface finishes. PCD saw blade is a cost effective investment for your difficult to machine materials.

|

OD(mm) |

Bore |

Kerf Thickness |

Plate Thickness |

Number of Teeth |

Grind |

|

305 |

25.4 |

3 |

2.5 |

120 |

TCG |

|

305 |

30 |

3 |

2.5 |

120 |

TCG |

|

355 |

25.4 |

3.2 |

2.7 |

120 |

TCG |

|

400 |

30 |

3.8 |

3.2 |

120 |

TCG |

|

450 |

30 |

4 |

3.5 |

120 |

TCG |

|

500 |

30 |

4.4 |

3.8 |

120 |

TCG |

|

550 |

30 |

4.4 |

3.8 |

120 |

TCG |

|

550 |

30 |

4.4 |

3.8 |

144 |

TCG |

|

600 |

30 |

4.8 |

4.2 |

144 |

TCG |

Customerization

OEM accepted, with customers' logo or without any logo are available because we are professional manufacturer of woodworking tools and metal cutting tools.

Packing Details

Blades are packaged separately in a paper box with a protective plastic bag inside. Outside are carton boxes that have been baling film-wrapped.

MARK is written on the outside.

Supported by worldwide air express and shipping by sea, including shipping to customers' designated forwarders, via TNT, FedEx, DHL, and UPS.

Trading Terms

We accept terms of EXW, FOB, CIF etc.

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives